1 Introduction

The purpose of this wiki document is to outline all of the changes we are making to our current (manual) Certificate of Compliance process.

Goals

- Automate our current C of C process therefor eliminating user error and bad practices.

- Automating this process will allow for greater efficiency of our Customer Experience Department. As a result, freeing them up to handle more demanding tasks in the queue.

Background and strategic fit

Since January 1st 2018 – June 24th 2018, we have sent 1,591 C of Cs at the time of shipment. This number does not include C of Cs created after an order has been placed (and possibly shipped) which is believed to be several hundred more.

Number of Orders Requesting C of Cs at Order Placement

01/01/18 - 03/29/18 (87 Days) = 755 C of Cs (694 Materials + 61 HACCP)

03/03/18 - 06/24/18 (86 Days) = 836 C of Cs (768 Materials + 68 HACCP) 11% increase

Total (174 Days) = 1,591 C of Cs (1,462 Materials + 129 HACCP)

Historically, when Customer Experience pulls an order from the queue that requests a C of C - these steps would be followed:

- The order gets placed with "Materials Certificate of Compliance" enabled (via Special Instructions popup window).

- CE determines which C of C is required, based on the specifications of the item.

- CE fills out the document with the required information.

- CE prints the document.

- A supervisor signs paper document.

- CE scans the document back into a digital format (PDF).

- CE emails the document to Shipping.

- Shipping prints the document and attaches it to the order before shipment.

Note: If CE forgets to procure this documentation at the time of order, shipping will eventually send an email into the queue asking for the documentation.

If our customer places an order on laddawn.com and enables the "Materials Certificate of Compliance" option themselves - these steps would take place:

- The order gets placed with "Materials Certificate of Compliance" enabled (via Special Instructions popup window).

- The order prints to the warehouse, alerting Shipping that C of C documentation is required.

- Shipping sends an email into the queue asking them to procure the required documentation.

- CE determines which C of C is required, based on the specifications of the item.

- CE fills out the document with the required information.

- CE prints the document.

- A supervisor signs paper document.

- CE scans the document back into a digital format (PDF).

- CE emails the document to Shipping.

- Shipping prints the document and attaches it to the order before shipment.

Note: Most often the C of C document is attached to a physical order; it's also very common for the documentation to be emailed directly to the customer - often before the product has even left our warehouse. Additionally, many customers request C of C documentation 'after the fact,' sometimes weeks/months after the order has shipped.

Over time we have adopted the bad practice of sending Word Documents (bypassing the printing & scanning of documents) directly to our customers. Therefore giving our customers the ability to alter these documents any way they wish, including having ‘easy access’ to our digital signatures found within these documents.

It is important to note, all of this is still possible regardless of the type of media we choose to send our customers. However, we probably shouldn’t be making it ‘this easy’ for them to alter our documents.

Lot Numbers

Before we can automate C of Cs on the web, we need to address the big problem surrounding lot numbers.

When Customer Experience pulls an order from the queue that requests a C of C with lot numbers – they must contact the appropriate warehouse and request the lot numbers. Once CE gets these numbers (after order fulfillment), only then can they complete the C of C document. All of this takes up time and has the potential for slowing down an order from leaving our warehouse.

We do not capture analytics quantifying how often customers request lot numbers on their C of Cs. However, it seems to be a very common request. And presumably will become an even bigger request, as our product line expands to include Clean Room items. Additionally, if we source those types of products, many of our end users will be closely tied to a Food Service, Medical or Scientific industry, all of which adhere to strict FDA guidelines.

In one of our previous meetings, there was confusion over what items (in our warehouse) displayed lot numbers. After some investigation, I found out that Laddawn asks all of our vendors to follow a specific labeling template (as pictured below).

| Label Template | Vendor Labels |

|---|---|

| The label above is a template we ask all of our vendors to copy. | As you can see, our vendors do a great job adhering to Laddawn’s label template. |

The majority of our vendors adhere to Laddawn’s labeling template. However, there are a handful of vendors that cannot create customized labels. In those cases, Laddawn will create the 2x2 label and send it to the vendor so they can place them onto each of the units.

Capturing Lot Numbers

The good news is that all items contain a lot number. The not so good news is that lot numbers do not get captured in Avante upon leaving our warehouse.

To address this problem, we may want to simplify the process of requesting and capturing lot numbers manually. To better explain this new workflow, I have outlined some of the steps below.

Scenario:

Solution and scope

What chu talkin' about Willis?

2 Definitions

C of C = Certificate of Compliance

CE = Customer Experience

3 Assumptions

<< List all assumptions made at the outset. If the design is based on a specific set of conditions or givens, list them here. If there is a desired environment or specific set of requirements that need to be met for the solution to be valid, list them here. >>

4 User Interaction and Design

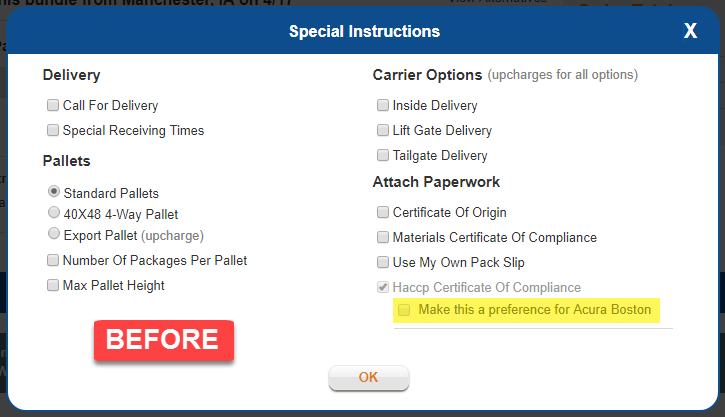

UI Changes | ||

|---|---|---|

| The screenshots pictured below highlight UI changes we will be making to laddawn.com. | ||

| No Selection (Material) / No Selection (HACCP) | No Selection (Material) / Automatic Selection (HACCP) | "Leaving this section blank would be criminal" |

The screenshot above is from an order that does not contain HACCP compliant items. However, we still allow the user to ask for HACCP compliant documentation. If a customer did ask for HACCP documentation, it is unlikely they would receive any as Shipping/Customer Experience would most likely catch this mistake when the order prints to the warehouse. | All HACCP compliant orders automatically receive the HACCP Certificate of Compliance (which is attached to all shipments). Considering this is mandatory (and automatic), we should not ask if the user wants to make this a preference on the Ship To level. | |

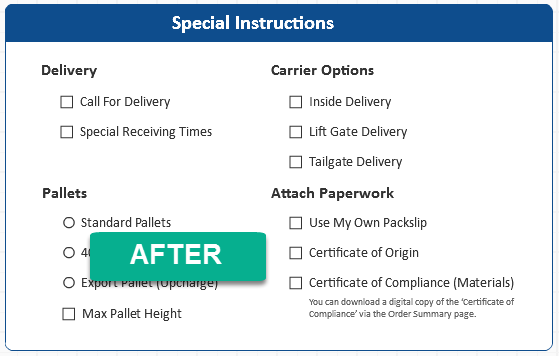

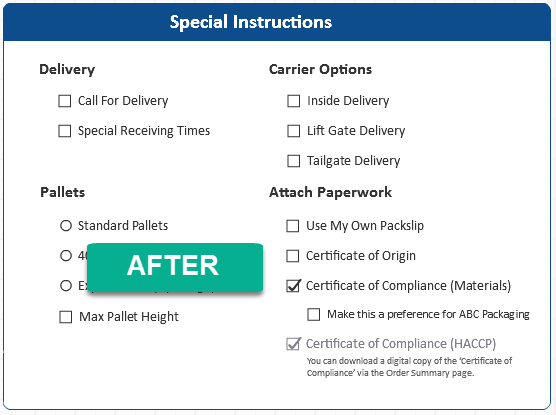

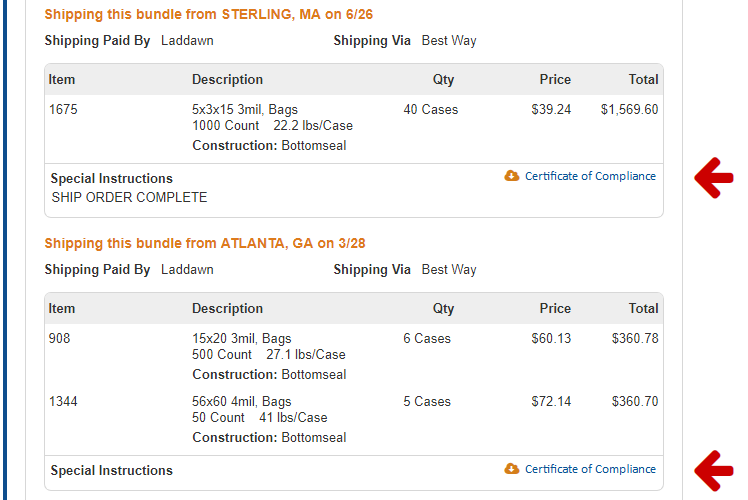

| No Selection (Material) / No Selection (HACCP) | No Selection (Material) / Automatic Selection (HACCP) | Download PDF |

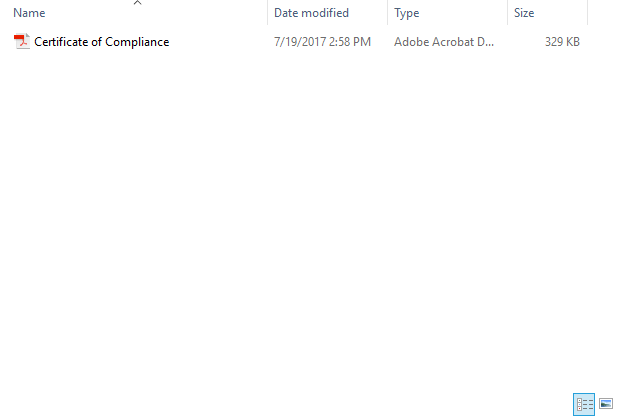

In the screenshot above, you will notice the removal of ‘Haccp Certificate of Compliance.’ It is not visible because ‘this’ order does not contain any HACCP compliant items. Additionally, we are not passing on the opportunity to teach our customer ‘this’ documentation is available for download. The helper text reads: “You can download a digital copy of the ‘Certificate of Compliance’ via the Order Summary page.” | If an order contains a HACCP compliant item, “Certificate of Compliance (HACCP)” becomes visible and appears in a selected but disabled state (similar to how we handle this today). You may have noticed we are not allowing the user to set “Certificate of Compliance (HACCP)” as a Ship To preference because this is already a mandatory preference for all Ship To's. | On the Order Summary page, we have included a link “Certificate of Compliance” located in the ‘Special Instructions’ section. If the user clicks on this link, they will be prompted to (download) save a single PDF file that contains one (or multiple) C of C’s that pertain to the bundle. Note: The "Certificate of Compliance" link should be available immediately after an order is placed. |

Does this C of C process also include NS orders?

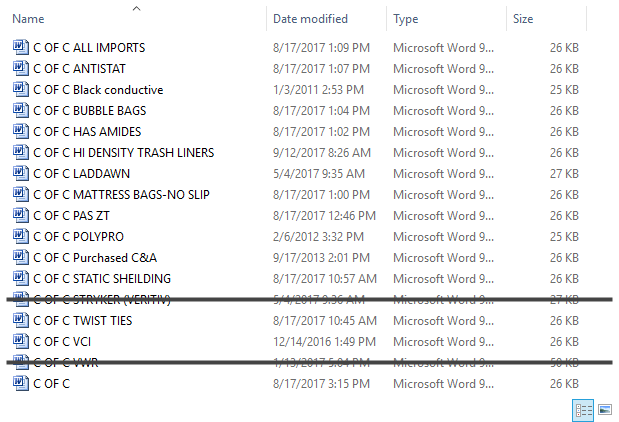

Document Files | ||

| The screenshots pictured below highlight changes we will be making to our C of C documents. | ||

| Multiple C of C Documents | ||

|---|---|---|

For every C of C request received, we rely heavily on Customer Experience to pick the appropriate document to send based on the items specifications. As of today, we currently have 15 C of C documents to choose from. | In the future, we will only have one ‘dynamic’ Certificate of Compliance document. The newly created document will not be accessible via our network folder (Z:\CertDocs). Instead, it will continue to be available at the time of shipment (if previously selected as an option) or downloaded locally via the “Certificate of Compliance” link found on the Order Summary page. | |

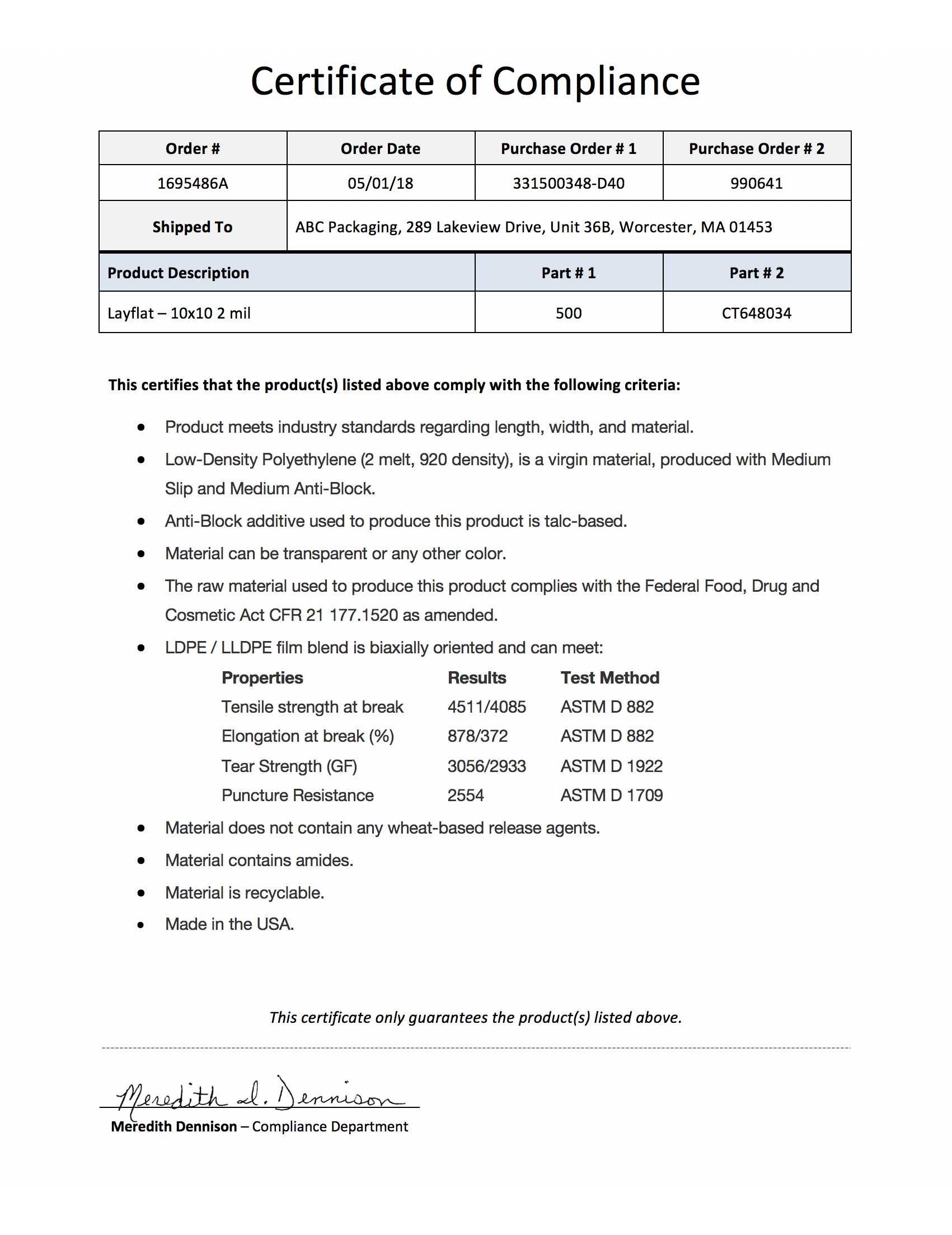

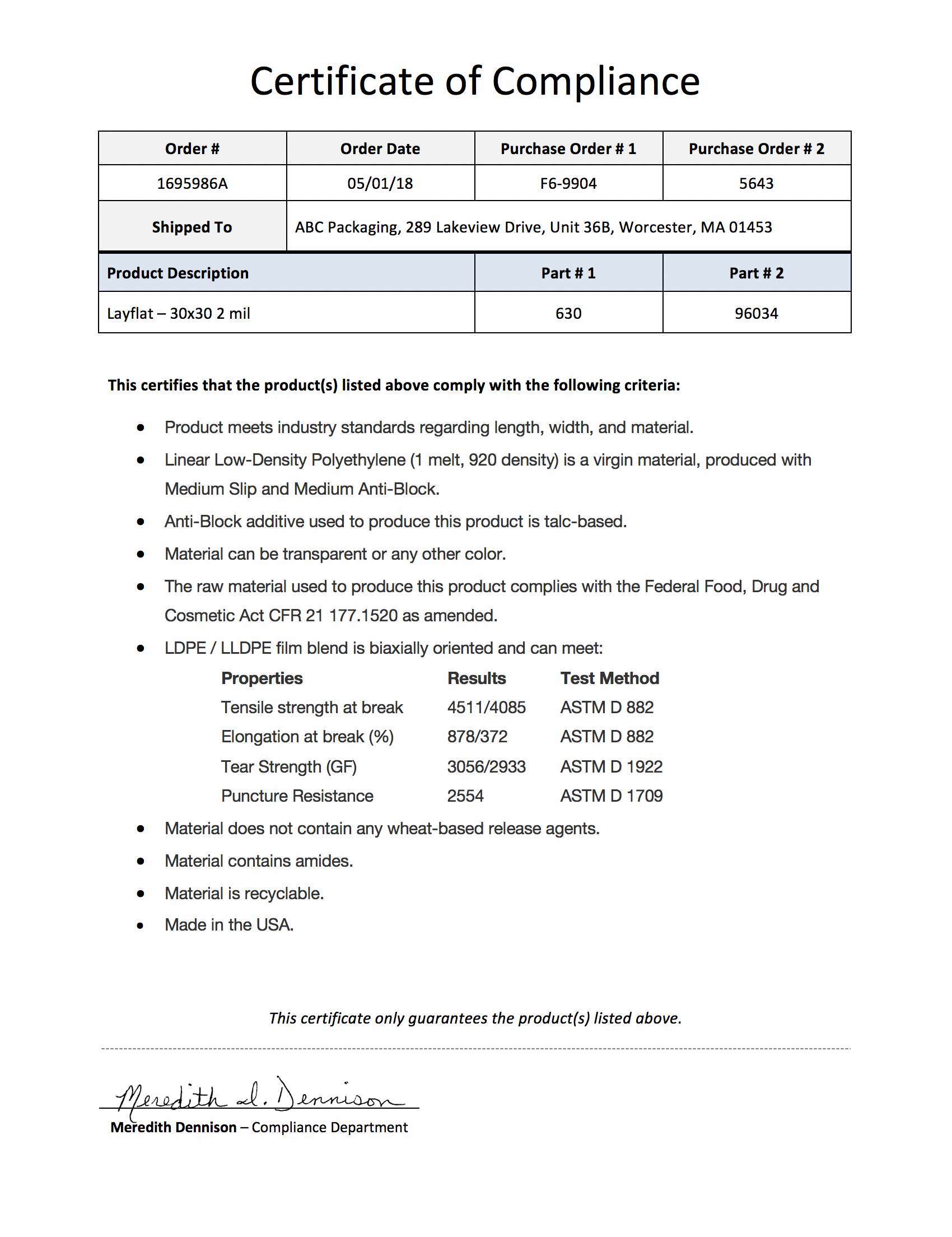

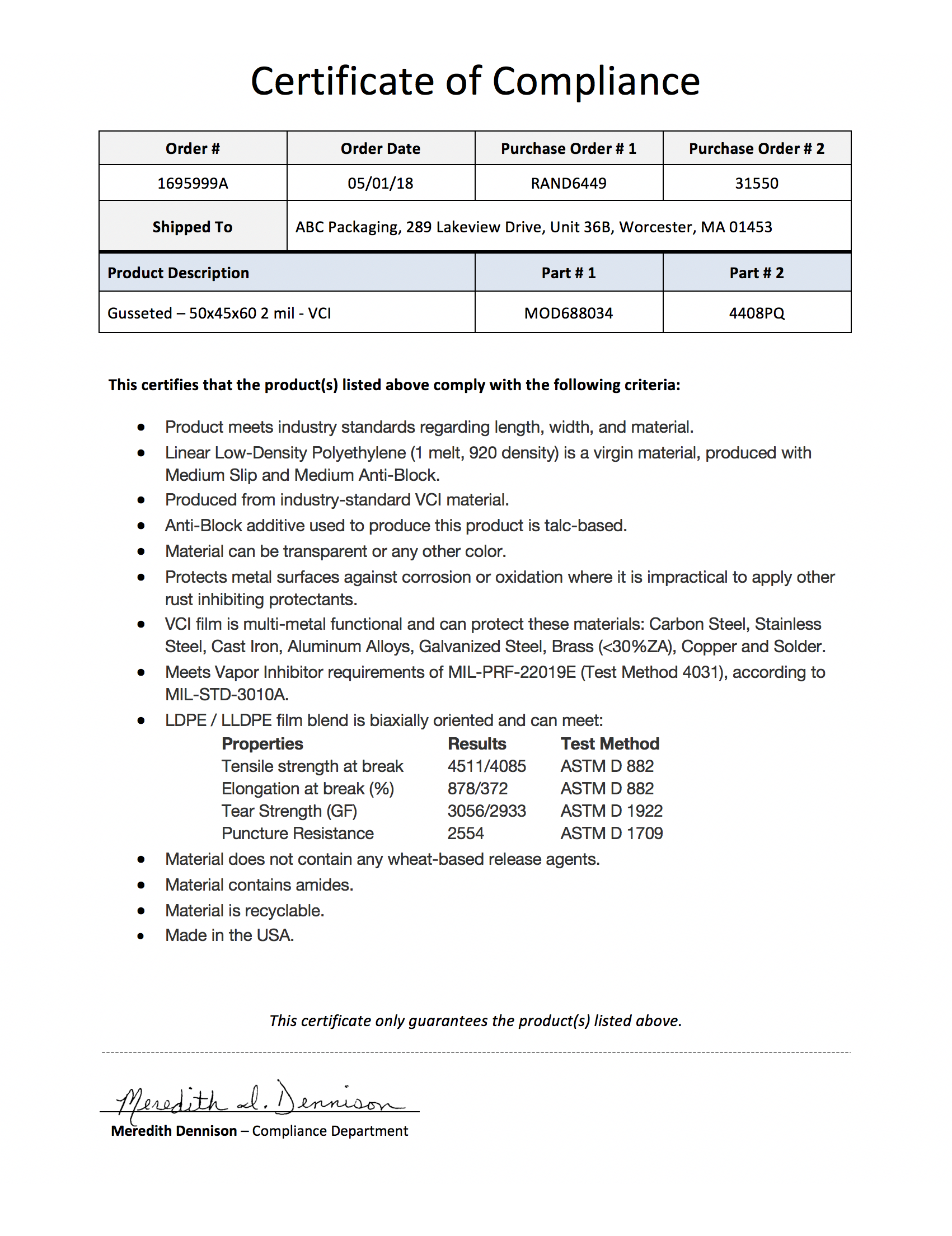

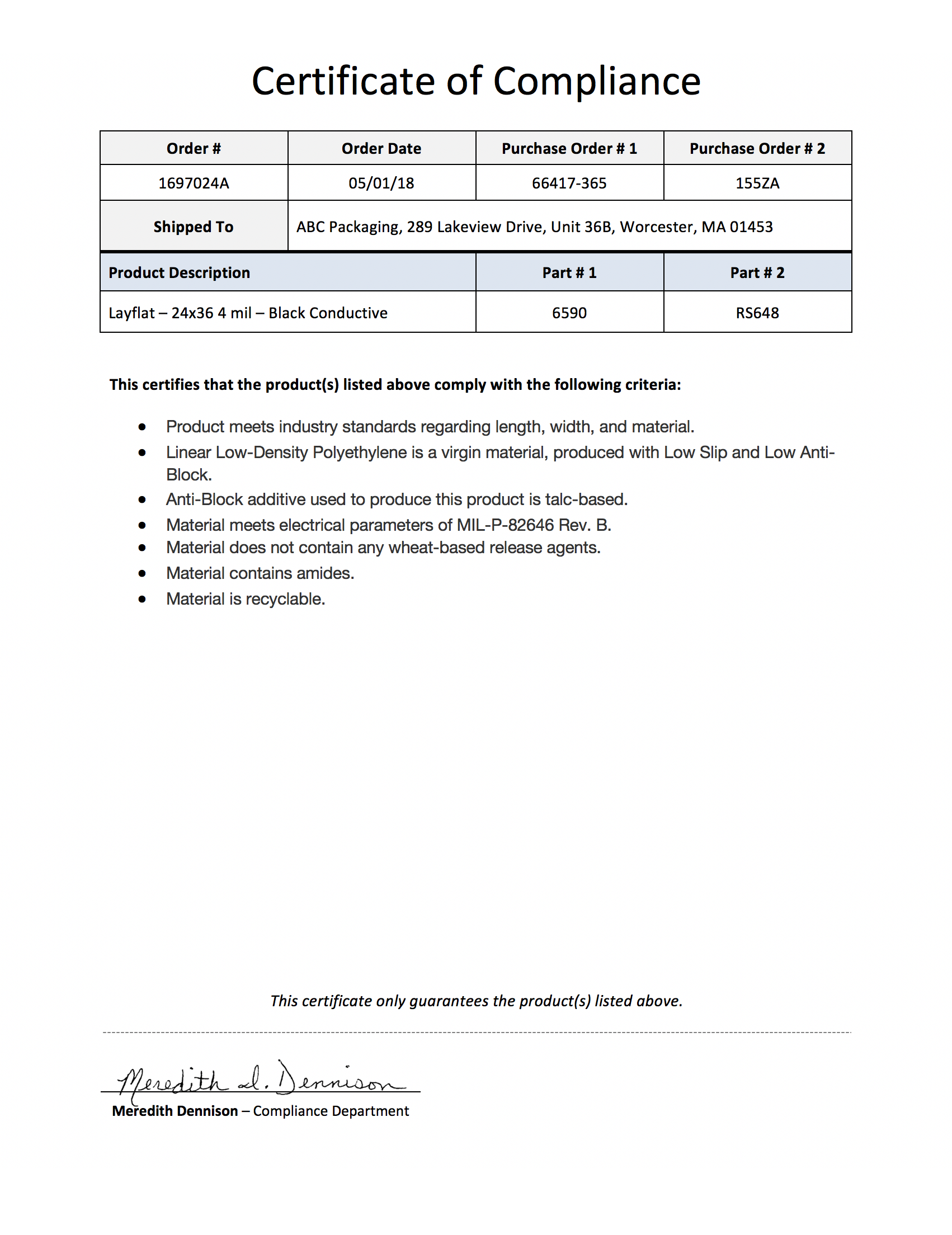

| C of C Documents: Templates & Examples | ||

|---|---|---|

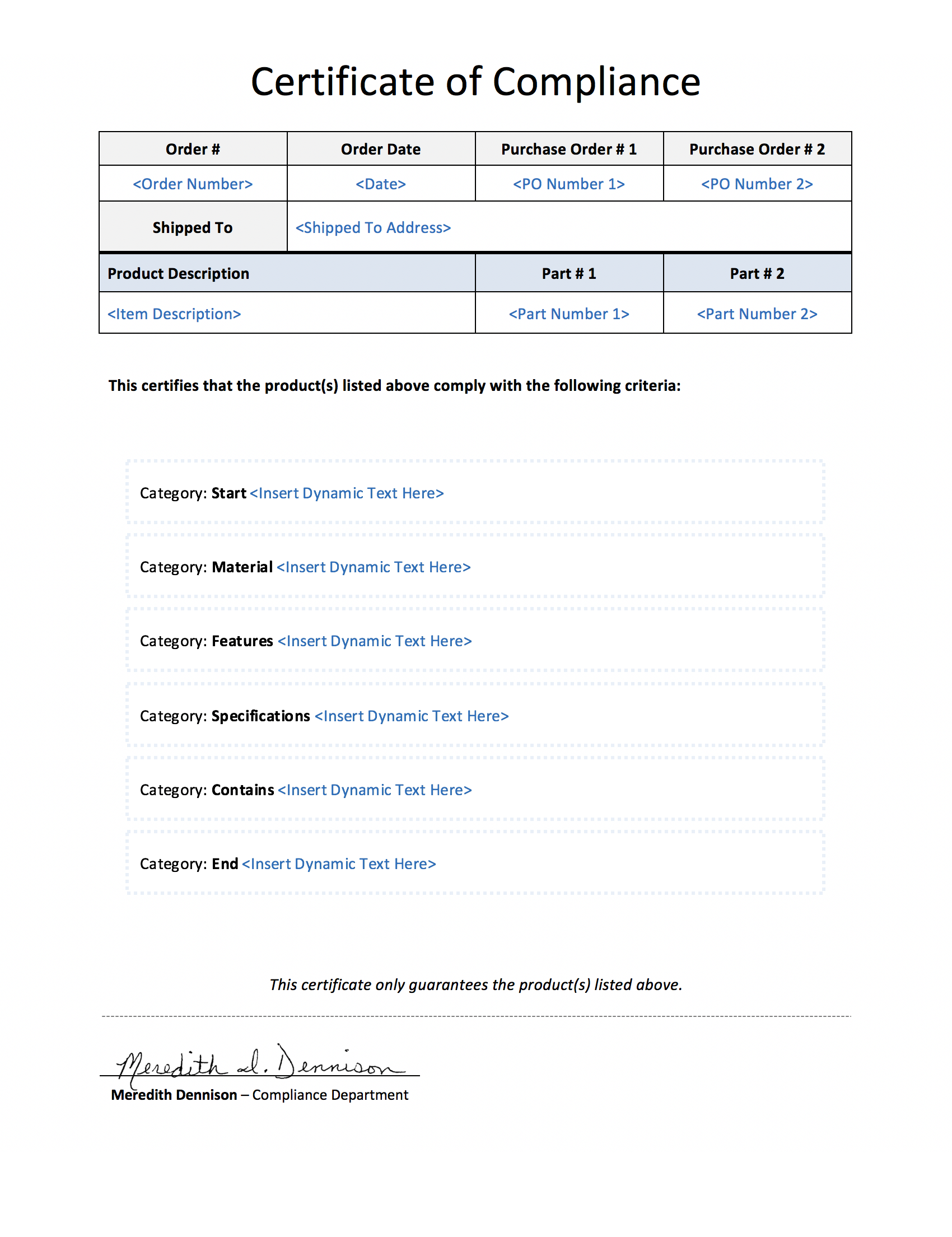

| Default Template | Item: Layflat Stock (Under 18" Width) | Item: Layflat Stock (Over 18" Width) |

All C of C's (except for HACCP) will follow the format depicted above. The header consists of placeholders that pertain to order and item details. The body consists of dynamic text, grouped by category. Note: The live document will not include any category annotations. It is only visible in the default template above to illustrate order sequence of dynamic text. If "Purchase Order # 2" or "Item # 2" do not contain any values, then their values should be "--". Note: "Purchase Order # 1", "Purchase Order # 2", "Part # 1" and "Part # 2" are working titles. | ||

| Item: VCI | Item: Black Conductive Stock | Item: Mattress Bags |

INSERT PRODUCT MATRIX HERE

| Dynamic Text (Materials) | ||||

|---|---|---|---|---|

| Legend: Product Type / Product Category / Material / Additive / Manufacturer | ||||

| Text String | Category | Sequence | Equal To | Not Equal To |

| Product meets industry standards regarding length, width, and material. | Start | 1-1 | Bags or Sheeting or Tubing | |

| Linear Low-Density Polyethylene (1 melt, 920 density) is a virgin material, produced with Medium Slip and Medium Anti-Block. | Material | 2-1 | Bags or Sheeting or Tubing and Standard LLDPE | |

| Linear Low-Density Polyethylene (1 melt, 920 density) is a virgin material, produced with Medium Anti-Block (and may contain trace amounts of Slip). | Material | 2-2 | Bags or Sheeting or Tubing and Non-Slip LLDPE | |

| Linear Low-Density Polyethylene is a virgin material, produced with Low Slip and Low Anti-Block. | Material | 2-3 | Bags or Sheeting or Tubing and Black Conductive | |

| Low-Density Polyethylene (2 melt, 920 density), is a virgin material, produced with Medium Slip and Medium Anti-Block. | Material | 2-4 | Bags or Sheeting or Tubing and Standard LDPE | |

| Low-Density Polyethylene (2 melt, 920 density), is a virgin material, produced with Medium Anti-Block (and may contain trace amounts of Slip). | Material | 2-5 | Bags or Sheeting or Tubing and Non-Slip LDPE | |

| High-Density Polyethylene is a virgin material. | Material | 2-6 | Bags or Sheeting or Tubing and HDPE | |

| Polypropylene is a virgin material, produced with Low Slip and Medium Anti-Block. | Material | 2-7 | Bags or Sheeting or Tubing and PP | |

| Material is paper and wire. | Material | 2-8 | Twist Tie | |

| Produced from industry-standard VCI material. | Material | 2-9 | Bags or Sheeting or Tubing and VCI | |

| Anti-Block additive used to produce this product is talc-based. | Material | 2-10 | Bags or Sheeting or Tubing | Non-Scratch |

| Material can be transparent or any other color. | Material | 2-11 | Bags or Sheeting or Tubing | Black Conductive |

| Material is pink in color. | Material | 2-12 | Bags or Sheeting or Tubing and Pink Color Anti-Static | |

| Metallic Static Shielding Bags provide Faraday Cage projection for highly sensitive components. | Features | 3-1 | Bags and Static Shielding | |

| Protects metal surfaces against corrosion or oxidation where it is impractical to apply other rust-inhibiting protectants. | Features | 3-2 | Bags or Sheeting or Tubing and VCI | |

| VCI film is multi-metal functional and can protect these materials: Carbon Steel, Stainless Steel, Cast Iron, Aluminum Alloys, Galvanized Steel, Brass (<30%ZA), Copper and Solder. | Features | 3-3 | Bags or Sheeting or Tubing and VCI | |

| The raw material used to produce this product complies with the Federal Food, Drug and Cosmetic Act CFR 21 177.1520 as amended. | Specifications | 4-1 | Bags or Sheeting or Tubing | Printed VCI or (Purchased) C&A |

| Meets Vapor Inhibitor requirements of MIL-PRF-22019E (Test Method 4031), according to MIL-STD-3010A. | Specifications | 4-2 | Bags or Sheeting or Tubing and VCI | |

| Material meets Federal Specification PPP-C-795. | Specifications | 4-3 | Bags and Bubble Bags | |

| Material meets MIL-P-82646 Rev. B. | Specifications | 4-4 | Bags or Sheeting or Tubing and Black Conductive | |

| LDPE / LLDPE film blend is biaxially oriented and can meet: (NEEDS WORK) | Specifications | 4-5 | Bags or Sheeting or Tubing and LDPE or LLDPE and Laddawn | |

| Material does not contain any wheat-based release agents. | Contains | 5-1 | Bags or Sheeting or Tubing | |

| Material contains amides. | Contains | 5-2 | Bags or Sheeting or Tubing | Non-Slip |

New: Material may contain trace amounts of amides. Old: Material does not contain amides. | Contains | 5-3 | Bags or Sheeting or Tubing and Non-Slip | |

| Material contains Anti-Static concentrate without amides. | Contains | 5-4 | Bags or Sheeting or Tubing and Anti-Static | |

| Material is recyclable. | End | 6-1 | Bags or Sheeting or Tubing | Static Shielding |

| Made in the USA. | End | 6-2 | Laddawn | |

Be sure to address the following as applicable:

- Worst case scenario for configuration details on MOD items - material & additives, color, printing, venting, packaging, construction

- CPU customers/orders

- NorthEast Poly Bag customers

- Fax-only customers/Optio forms

- Analytics

- Customer experience procedures

- Other????

Not Doing

5 Testing

<< Optionally include a test plan here. >>

6 Change management and rollout planning

<< Which departments are affected by these changes? What are the possible negative perceptions of these changes, and how do we manage them? Articulate "what's in it for me?" for all internal and external stakeholders. Are call scripts necessary? Is advance customer outreach/communication necessary? What lead time is needed for training and other advance preparations? >>