| Release Date | TBD |

|---|---|

Document Status | FINAL |

| Document Owner | |

| Ticket # | TBA |

Introduction

The purpose of this wiki document is to outline all of the changes we are making to our current (manual) Certificate of Compliance process.

Goals

- Automate our current C of C process therefor eliminating user error and bad practices.

- Automating this process will allow for greater efficiency of our Customer Experience Department. As a result, freeing them up to handle more demanding tasks in the queue.

Background

Since January 1st 2018 - June 24th 2018, we have sent 1,591 C of C's at the time of shipment. This number does not include C of C's created after an order has been placed (and possibly shipped) which is believed to be several hundred more.

C of C Requests

01/01/18 - 03/29/18 (87 Days) = 755 C of C's (694 Materials + 61 HACCP)

03/30/18 - 06/24/18 (86 Days) = 836 C of C's (768 Materials + 68 HACCP) 11% increase

Total (174 Days) = 1,591 C of C's (1,462 Materials + 129 HACCP)

- The information above does not include customers who request C of C's after an order has been placed.

Historically, when Customer Experience pulls an order from the queue that requests a C of C - these steps would be followed:

- The order gets placed with "Materials Certificate of Compliance" enabled (via Special Instructions popup window).

- CE determines which C of C is required, based on the specifications of the item.

- CE fills out the document with the required information.

- CE prints the document.

- A supervisor signs paper document.

- CE scans the document back into a digital format (PDF).

- CE emails the document to Shipping.

- Shipping prints the document and attaches it to the order before shipment.

Note: If CE forgets to procure this documentation at the time of order, shipping will eventually send an email into the queue asking for the documentation.

If our customer places an order on laddawn.com and enables the "Materials Certificate of Compliance" option themselves - these steps would take place:

- The order gets placed with "Materials Certificate of Compliance" enabled (via Special Instructions popup window).

- The order prints to the warehouse, alerting Shipping that C of C documentation is required.

- Shipping sends an email into the queue asking them to procure the required documentation.

- CE determines which C of C is required, based on the specifications of the item.

- CE fills out the document with the required information.

- CE prints the document.

- A supervisor signs paper document.

- CE scans the document back into a digital format (PDF).

- CE emails the document to Shipping.

- Shipping prints the document and attaches it to the order before shipment.

Note: Most often the C of C document is attached to a physical order; it's also very common for the documentation to be emailed directly to the customer - often before the product has even left our warehouse. Additionally, many customers request C of C documentation 'after the fact,' sometimes weeks/months after the order has shipped.

Over time we have adopted the bad practice of sending Word Documents (bypassing the printing & scanning of documents) directly to our customers. Therefore giving our customers the ability to alter these documents any way they wish, including having ‘easy access’ to our digital signatures found within these documents.

It is important to note, all of this is still possible regardless of the type of media we choose to send our customers. However, we probably shouldn’t be making it ‘this easy’ for them to alter our documents.

UI Changes

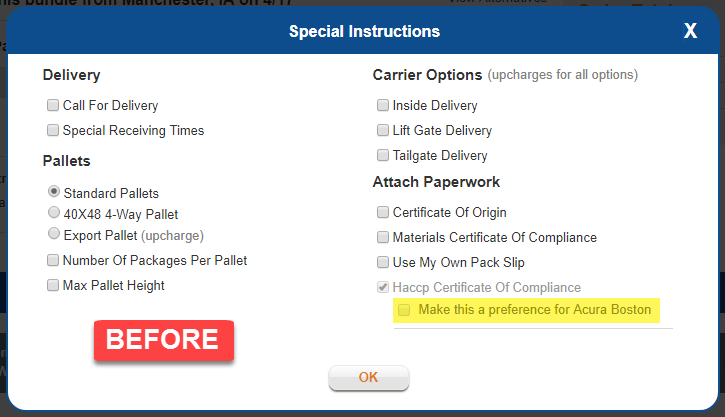

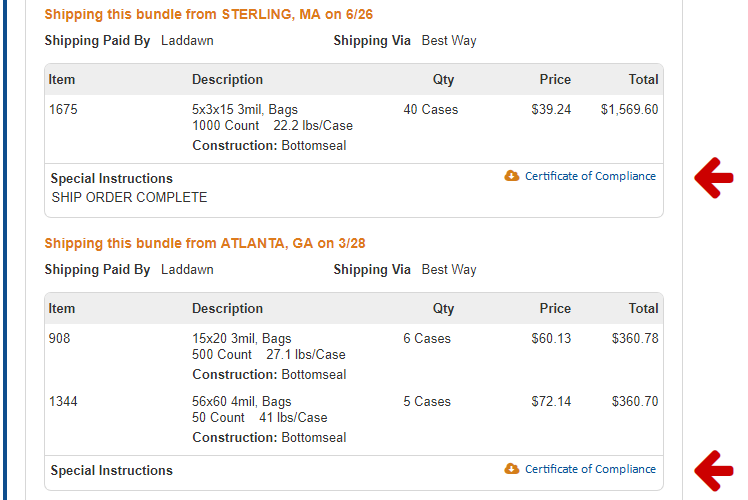

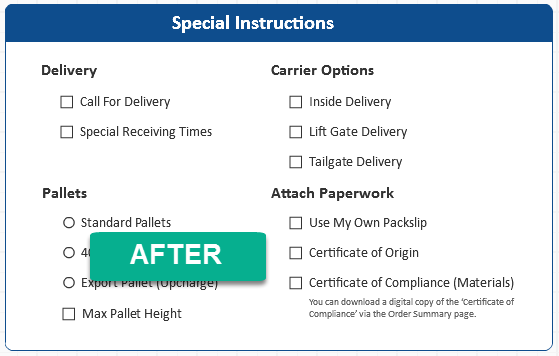

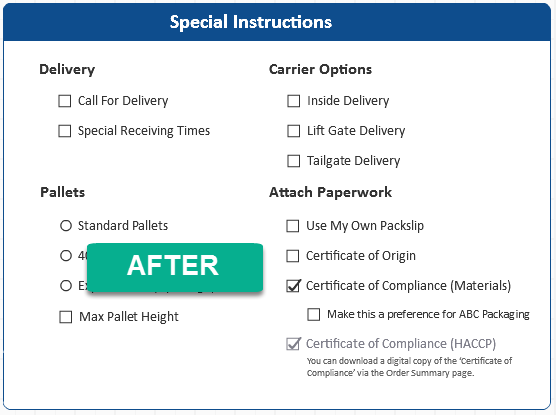

The screenshots below highlight some UI changes we will be making which also include improvements to how we handle HACCP orders.

| Non-HACCP Order | HACCP Order | Order Summary |

|---|---|---|

The before screenshot is from an order that does not contain HACCP compliant items. | The before screenshot is from an order that does contain HACCP compliant items. As you can see, "Haccp Certificate of Compliance" is checked and disabled - because this selection is mandatory. Considering this selection is mandatory across all HACCP orders - we should not allow for the user to set this as a preference per Ship To. | Provide the user with a means of downloading these documents after an order has been placed. |

Recommendations:

| Recommendations:

| Recommendations:

|

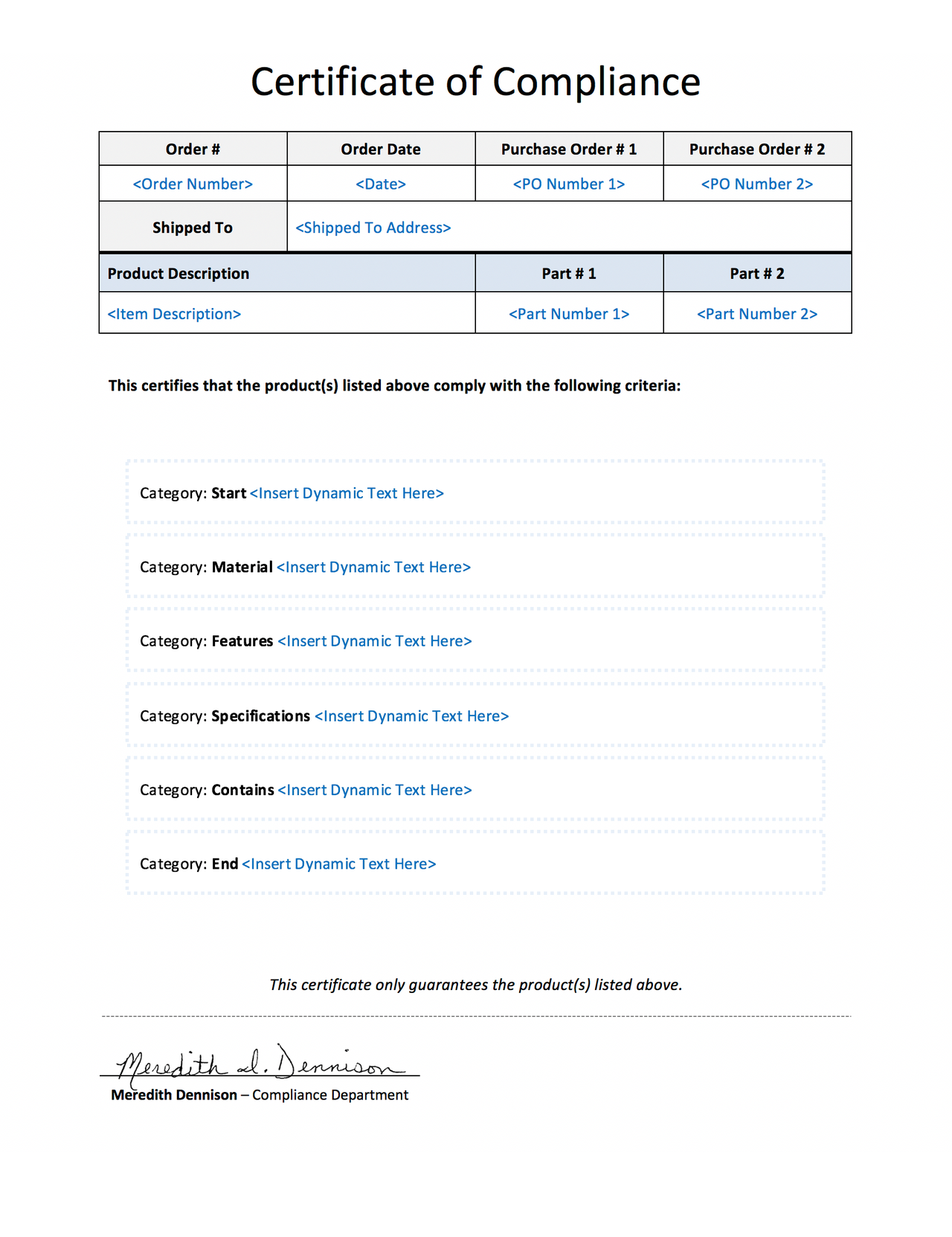

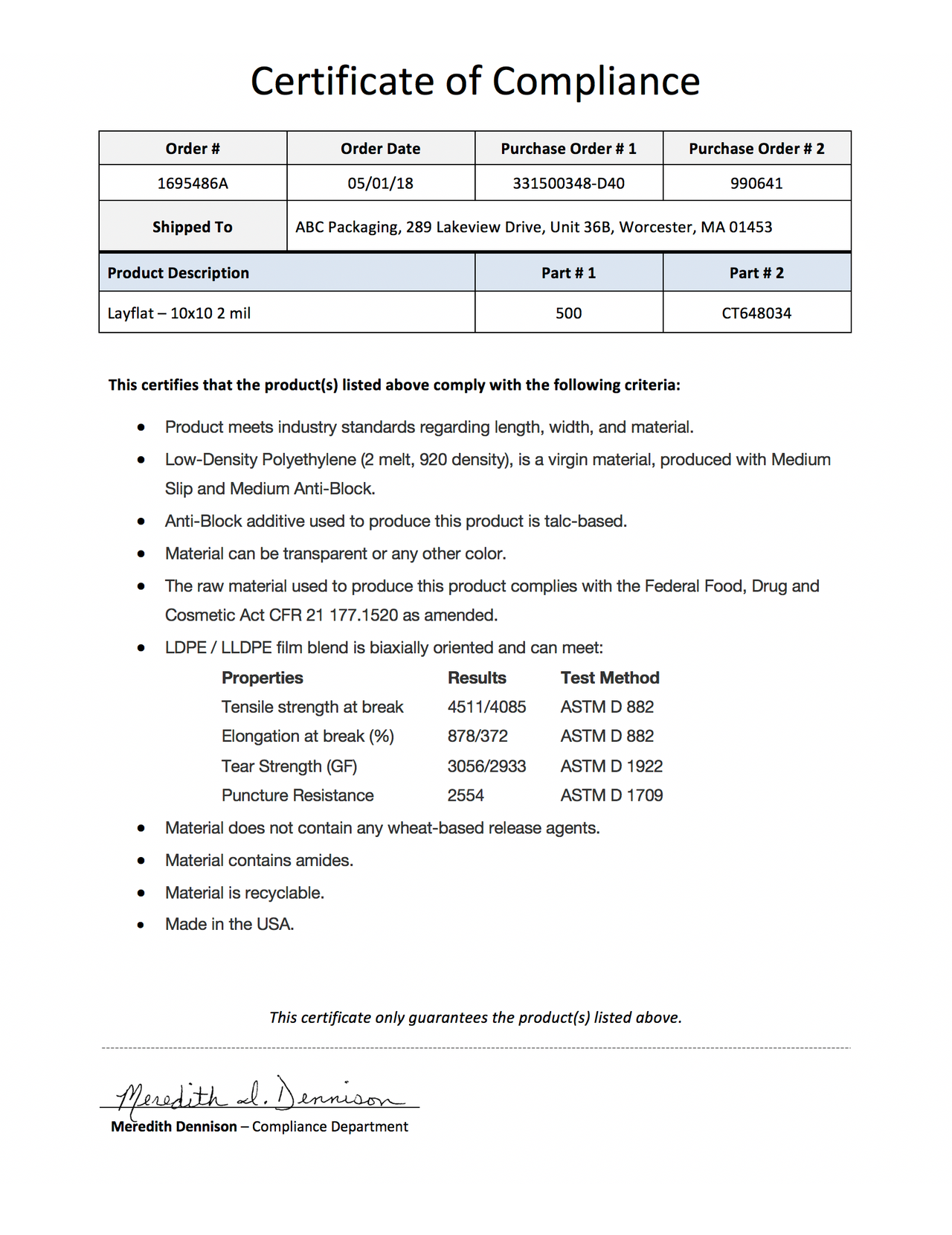

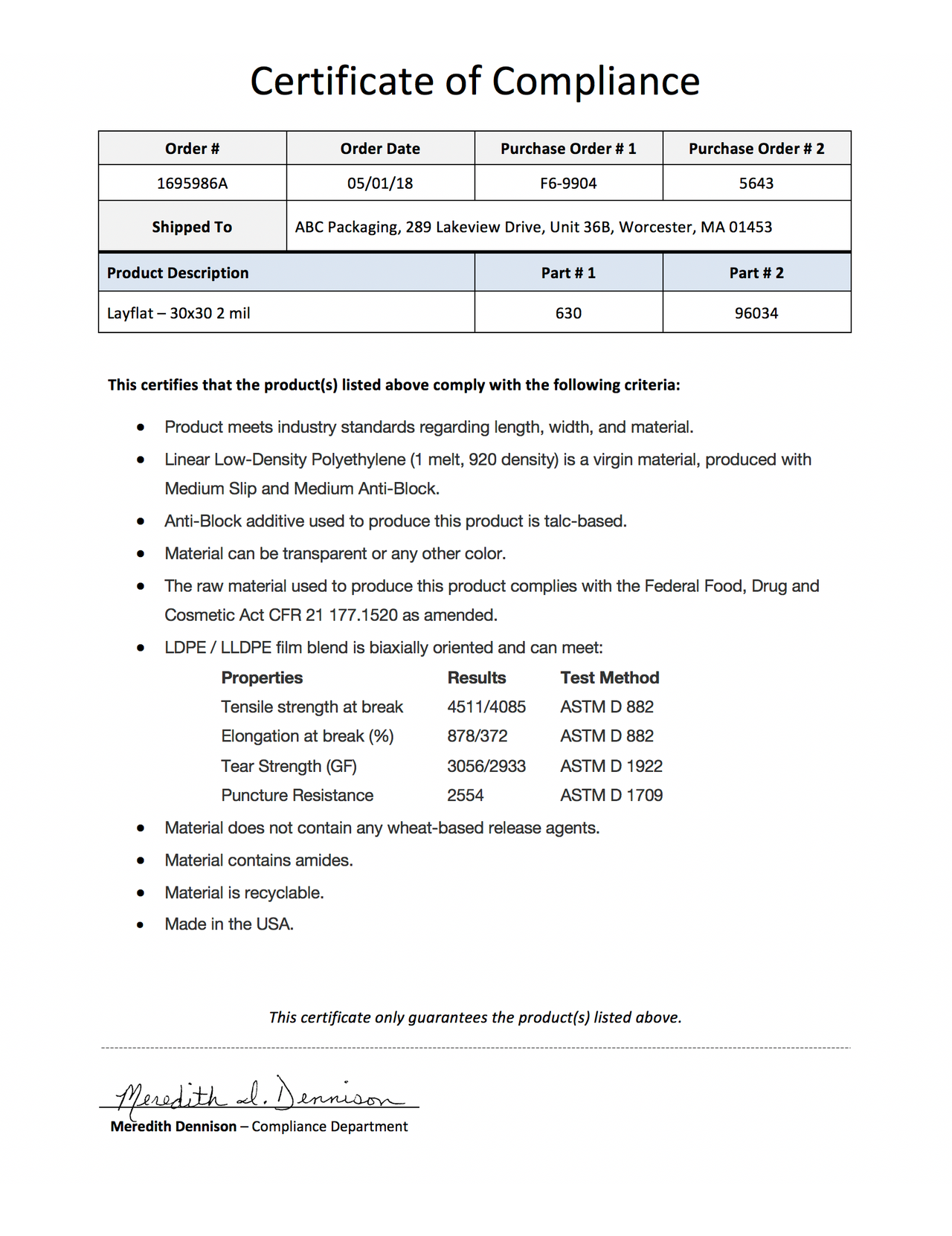

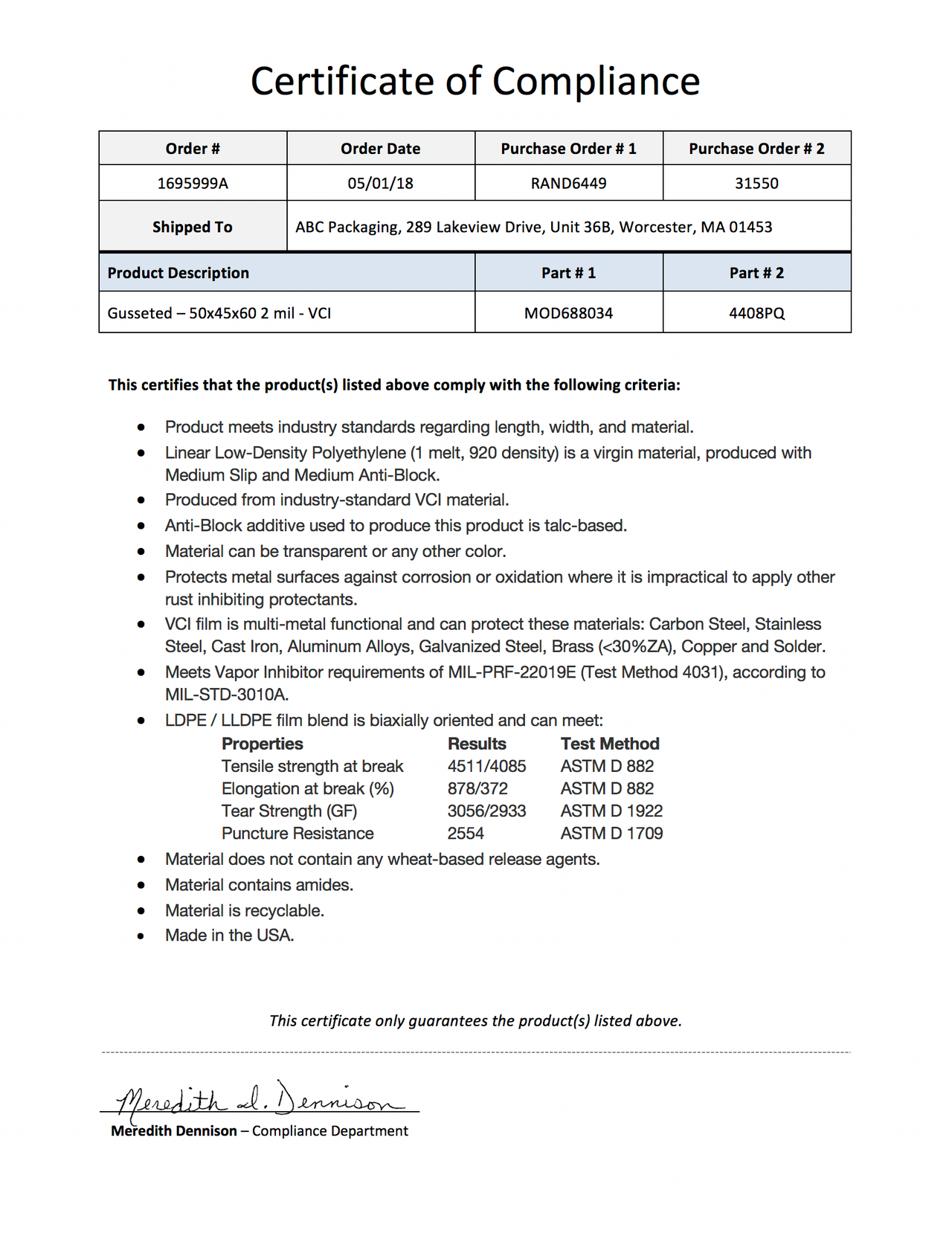

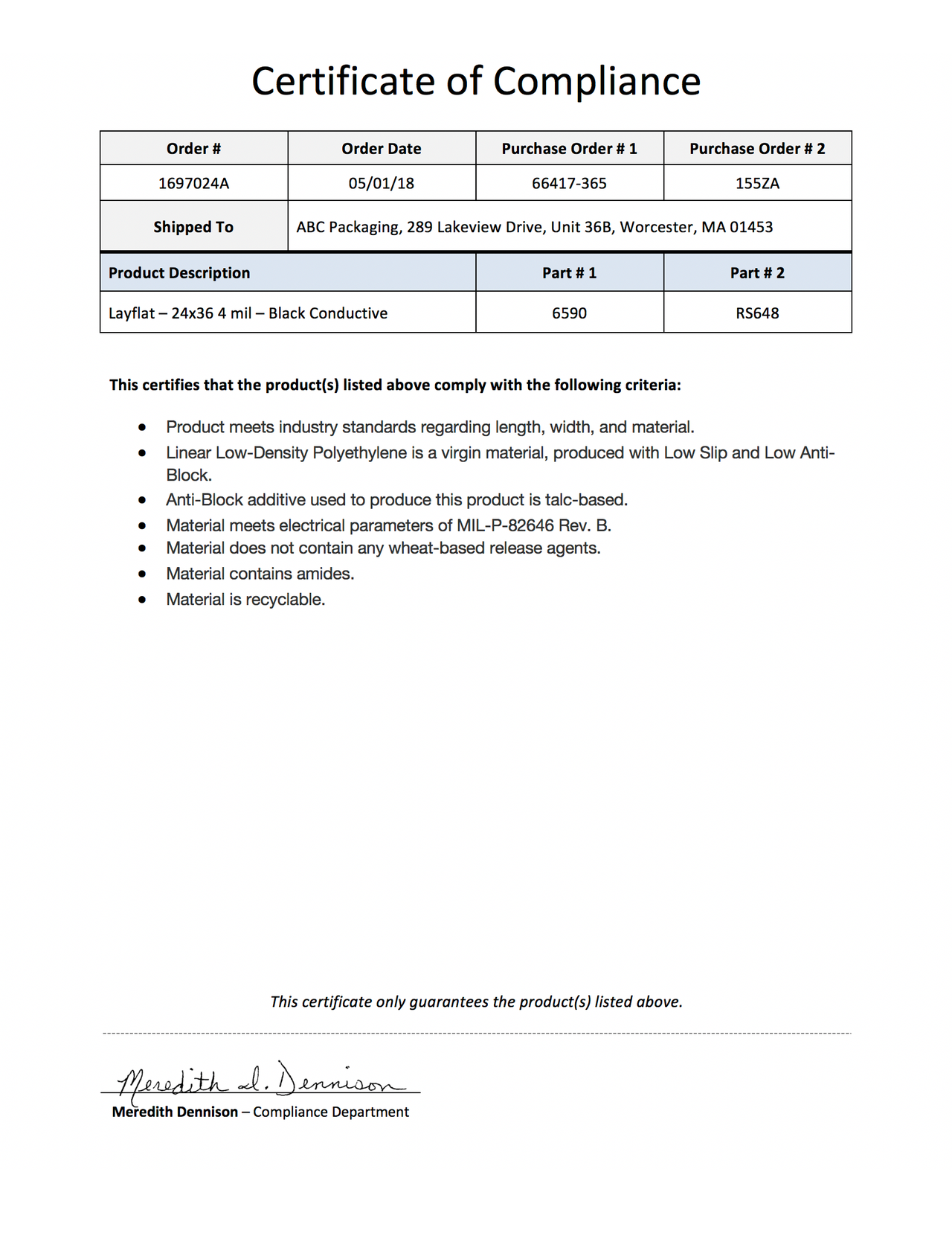

Document Template

| Default Template | Layflat (Under 18" Width) | Layflat (Over 18" Width) | Gusseted (VCI) | Layflat (Black Conductive) |

|---|---|---|---|---|

Multiple Items

When a customer requests a C of C, they're requesting it on the bundling level - which may contain multiple items. C of C documents should display multiple items as long as all items meet the criteria displayed in the document. The templates above do not illustrate this, but the item description and part numbers should but displayed underneath each other.

Dynamic Text

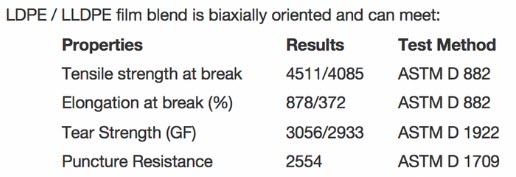

| Legend: Product Type / Product Category / Material / Additive / Manufacturer | ||||

| Text String | Category | Sequence | Equal To | Not Equal To |

|---|---|---|---|---|

| Product meets industry standards regarding length, width, and material. | Start | 1-1 | Bags or Sheeting or Tubing | |

| Linear Low-Density Polyethylene (1 melt, 920 density) is a virgin material, produced with Medium Slip and Medium Anti-Block. | Material | 2-1 | Bags or Sheeting or Tubing and Standard LLDPE | |

| Linear Low-Density Polyethylene (1 melt, 920 density) is a virgin material, produced with Medium Anti-Block (and may contain trace amounts of Slip). | Material | 2-2 | Bags or Sheeting or Tubing and Non-Slip LLDPE | |

| Linear Low-Density Polyethylene is a virgin material, produced with Low Slip and Low Anti-Block. | Material | 2-3 | Bags or Sheeting or Tubing and Black Conductive | |

| Low-Density Polyethylene (2 melt, 920 density), is a virgin material, produced with Medium Slip and Medium Anti-Block. | Material | 2-4 | Bags or Sheeting or Tubing and Standard LDPE | |

| Low-Density Polyethylene (2 melt, 920 density), is a virgin material, produced with Medium Anti-Block (and may contain trace amounts of Slip). | Material | 2-5 | Bags or Sheeting or Tubing and Non-Slip LDPE | |

| High-Density Polyethylene is a virgin material. | Material | 2-6 | Bags or Sheeting or Tubing and HDPE | |

| Polypropylene is a virgin material, produced with Low Slip and Medium Anti-Block. | Material | 2-7 | Bags or Sheeting or Tubing and PP | |

| Material is paper and wire. | Material | 2-8 | Twist Tie | |

| Produced from industry-standard VCI material. | Material | 2-9 | Bags or Sheeting or Tubing and VCI | |

| Anti-Block additive used to produce this product is talc-based. | Material | 2-10 | Bags or Sheeting or Tubing | Non-Scratch |

| Material can be transparent or any other color. | Material | 2-11 | Bags or Sheeting or Tubing | Black Conductive |

| Metallic Static Shielding Bags provide Faraday Cage projection for highly sensitive components. | Features | 3-1 | Bags and Static Shielding | |

| Protects metal surfaces against corrosion or oxidation where it is impractical to apply other rust-inhibiting protectants. | Features | 3-2 | Bags or Sheeting or Tubing and VCI | |

| VCI film is multi-metal functional and can protect these materials: Carbon Steel, Stainless Steel, Cast Iron, Aluminum Alloys, Galvanized Steel, Brass (<30%ZA), Copper and Solder. | Features | 3-3 | Bags or Sheeting or Tubing and VCI | |

| Meets Vapor Inhibitor requirements of MIL-PRF-22019E (Test Method 4031), according to MIL-STD-3010A. | Specifications | 4-2 | Bags or Sheeting or Tubing and VCI | |

| Material meets Federal Specification PPP-C-795. | Specifications | 4-3 | Bags and Bubble Bags | |

| Material meets MIL-P-82646 Rev. B. | Specifications | 4-4 | Bags or Sheeting or Tubing and Black Conductive | |

| Specifications | 4-5 | Bags or Sheeting or Tubing and LDPE or LLDPE and Laddawn | ||

| Material contains amides. | Contains | 5-2 | Bags or Sheeting or Tubing | Non-Slip |

Material may contain trace amounts of amides. | Contains | 5-3 | Bags or Sheeting or Tubing and Non-Slip | |

| Material contains Anti-Static concentrate without amides. | Contains | 5-4 | Bags or Sheeting or Tubing and Anti-Static | |

| Material is recyclable. | End | 6-1 | Bags or Sheeting or Tubing | Static Shielding |

| Made in the USA. | End | 6-2 | Laddawn | |

.

Sequence

The sequence column specifies the order in which that string of text should appear on the document.

Open Questions

| Question | Answer |

|---|---|

| Will we have the ability to offer automated C of C's on non-stock items? | No. This only applies to stock and mod items. |

| Will we have the ability to generate C of C's after an order has been placed? Perhaps via a download link on the summary page (in each bundling section). | Yes. However, this link should only be visible AFTER a bundle has shipped. |

| Do we need to retain copies of C of C's that are generated? | No (Per Meredith) We currently do not retain any copies of HACCP documentation, so we do not need to preserve these either. |