Scope

- Printing on all sides of an item

- Layflat and gusseted - front and back

- Gussets on bags with with bottom gussets (since there's little to no demand for printing on side gussets, we're skipping that)

- Printing on lips for lip & tape and polymailers

- Better representation of zip tops in designer (show zippered portion and skirt)

- Cropping tool

Preliminary design considerations and questions

Type of bag - layflat, side gusset, bottom gusset - and construction - BS/SW - dictate number of plates, display, print method(s) allowed. In addition, all co-extruded poly mailer bags are always sideweld, and always full bleed (involves rotogravure process) - Rue La La for example. The "art" is actually the black color. The text is reversed out.

Please note: David also shared a physical sample of a lip and tape bag (not a co-ex mailer) and it had clear margins for printing, ie, was not full bleed.

Cut and fold construction may require only one plate per color for multi-sided printing v. printing on both sides of tube at same time, will require two plates per color for each side. Forcing the former to be one plate is probably advantageous to users in most cases, though it does mean the separate portions of the art will not have separate plates that can be independently reused (for example, a nutrition label).

La Perla is an example of a side weld bag, designer should show one continuous surface to print on.

White Meats is an example of a bottom seal bag, with opening at top of tube; designer should have you design one side at a time. Or should we show as a continuous surface no matter what?

Orientation: Should continuous surface designer displays always be vertical, so at least one side is right side up, or always be horizontal (both sides show art sideways), or should it depend on aspect ratio - what will fit best on the screen? For some reason, wicketed bag drawings from our vendors are always vertical. But other bag types are typically horizontal?

Regardless of how the bag is laid out in the designer, a static front/back viewer is needed within the designer - so you can look at your work in its intended orientation before committing to the Find. The drawings will likely need to show both continuous surface and front/back (and other "sides" - bottom gusset, lip, etc.) in their intended orientations - not all on one page of course.

Do we need any special tricks for art placement? For example, assuming that if you place art on the back side of a layflat bag, we'll automatically rotate it so its upside down? That could be presumptuous on are part, if the user already has their art in the right orientation. I think we're leaning toward the user having to rotate it themselves.

Also, when you place art on a mailer or other bag with a lip, and you drag it to the far left edge, does it cut off there or automatically wrap over the far right edge?

We should consider expanding the area beneath the widget for print designer - especially if we have continuous surfaces with horizontal layout. Even if we go with vertical layouts, more space could help with tools and job aids.

Additional sample bag drawings

Next steps

David to produce a matrix of product types with features and construction that will dictate printing, plates, etc. Done.

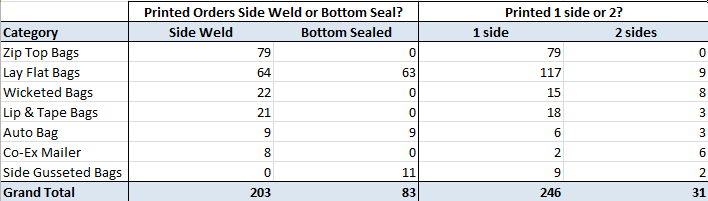

Attached is the matrix that shows the printed orders that we did over a 10 month period for MP categories (plus the manual ones we did in Avante for these categories).

It was surprising how many lay flat bags are bottom seal! What I had to do to get this information was consult with our suppliers to get their rule set that is used to decide if an order for printed lay flat bags is run side weld or bottom seal. Some of the logic used to decide this is straight forward, and other parts is more touch and feel;

1. 4 mil or greater is run bottom seal

2. Greater than 21” in length or width defaults to bottom seal

3. If the print requires tight registration side weld is preferred.

4. If the order is less than 1000#s and is simple artwork then bottom seal is preferredThere are reasons for each one of these points, but I figure I keep short and sweet.

Derek to do some sketches and post to Invision (please invite everyone).