1 Introduction

Incorporate HACCP manufacturing into widget and ordering and shipping processes.

Goals

- Increase sales and ROI on HACCP facilities. Automate manual processes.

Background and strategic fit

- We have invested a great deal in making our Iowa and Nevada plants comply with HACCP for food packaging. But we are not yet recovering these costs in the form of upcharges.

- The availability of HACCP-certified products is not discoverable on our website, leaving potential sales on the table.

- Exposing HACCP on the web will help us determine if further investment in making Atlanta, Dallas and Sterling HACCP compliant is warranted.

- Customers cannot order HACCP products on the web directly. CE must manually select the right plant and/or quote the order as nonstock. Ensuring certification is included with paperwork when products ship is a manual processes.

Solution and scope

Add branches to nested menus that include HACCP-eligible products. For initial release we will only show results for MOD, and not stock. Printing and VCI will continue to be unavailable for HACCP.

2 Definitions

HACCP - Hazard Analysis Critical Control Points - is a management system in which food safety is addressed through the analysis and control of biological, chemical, and physical hazards from raw material production, procurement and handling, to manufacturing, distribution and consumption of the finished product.

Source: FDA

HACCP compliance requires strict cleanliness and pest control; workers on our manufacturing lines must wear hairnets (or hats) and beard-nets. No food or uncovered drinks are allowed near the lines. HACCP requires annual third party audits to be conducted at each plant.

3 Assumptions

We are launching this before Atlanta and Dallas are made HACCP-compliant.

4 User Interaction and Design

A. Nested category menus

We will insert new branches in the menu for products that can be made at Laddawn facilities which are HACCP compliant. When the user selects categories from these branches, logic behind the scenes forces the result to come from the closest HACCP-compliant manufacturing facility. These are in effect new categories and will need new category codes. (They will be categories we make but do not stock, which is scenario 3 for advanced keyword searching.)

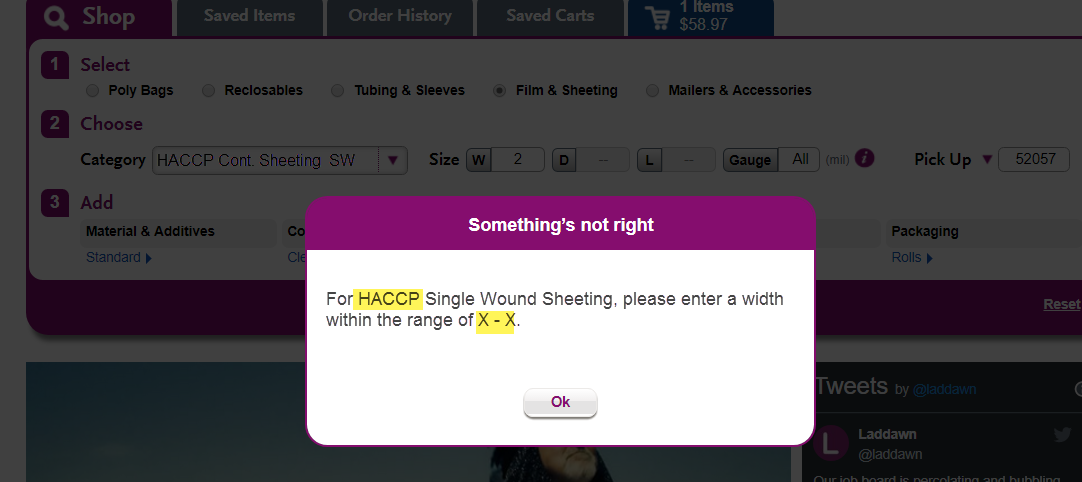

Each HACCP category will need to have its own dimension ranges based on the combined capabilities of the HACCP plants in operation; if the dimensions are something that none of the HACCP facilities can make, we will give a "something's not right error"; please be sure the error references HACCP as part of the category name, as shown below:

Even if the size entered for a HACCP menu item is something we typically import, if we can make it, we will quote it.

Menu modifications

POLY BAGS

Within Food Service, before >Ice | Cold Storage:

>HACCP

Layflat

Gusseted

>Ice | Cold Storage

Layflat

Gusseted

Pallet Top Covers

TUBING & SLEEVES

After Gusseted Sleeves:

>HACCP

Layflat Tubing

Gusseted Tubing

Layflat Sleeves

Gusseted Sleeves

FILM & SHEETING

After Shrink Bundling:

>HACCP

>Continuous Sheeting

Single Wound

Centerfold

Gusseted

Individually Cut Sheets in Cases

>Perforated Sheets on Rolls

Single Wound

Centerfold

Gusseted

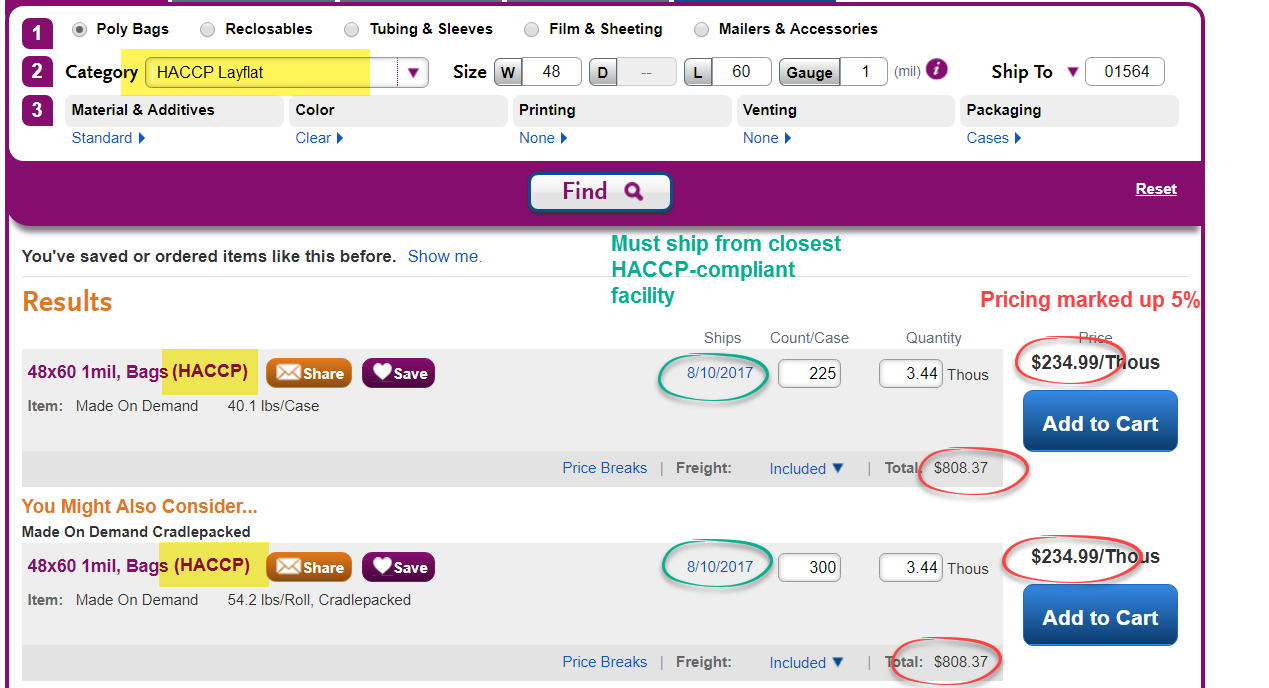

B. Results

Zip code validation

If the user chooses a HACCP category and a non-compliant pick up zip code, or a compliant zip code that cannot make that particular item, we will generate special messaging above the result indicating that the requested item cannot be made at the chosen facility.

"This item is not available for pick up in Iowa. Enter a ship to zip code or select "Pick Up - Reno" to continue."

We would like to employ this logic for any items that cannot be picked up at the chosen pick up facility. The pick up facility referenced in the second sentence above should be the next closest facility that makes the requested item. This would resolve a longstganding bug with the way this situation is currently handled. Please see HelpDesk ticket 11934.

Main results

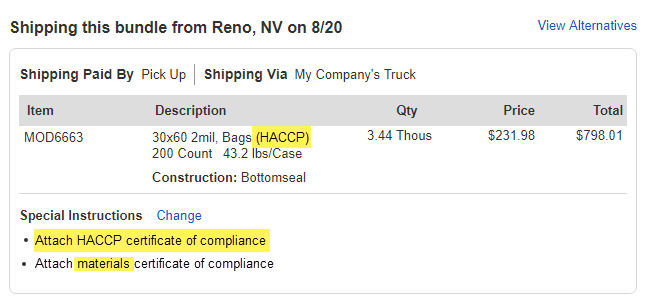

Append "(HACCP)" to the product headline.

Tack an additional 5% on to pricing.

Ensure availability popup reflects closest HACCP-compliant facility.

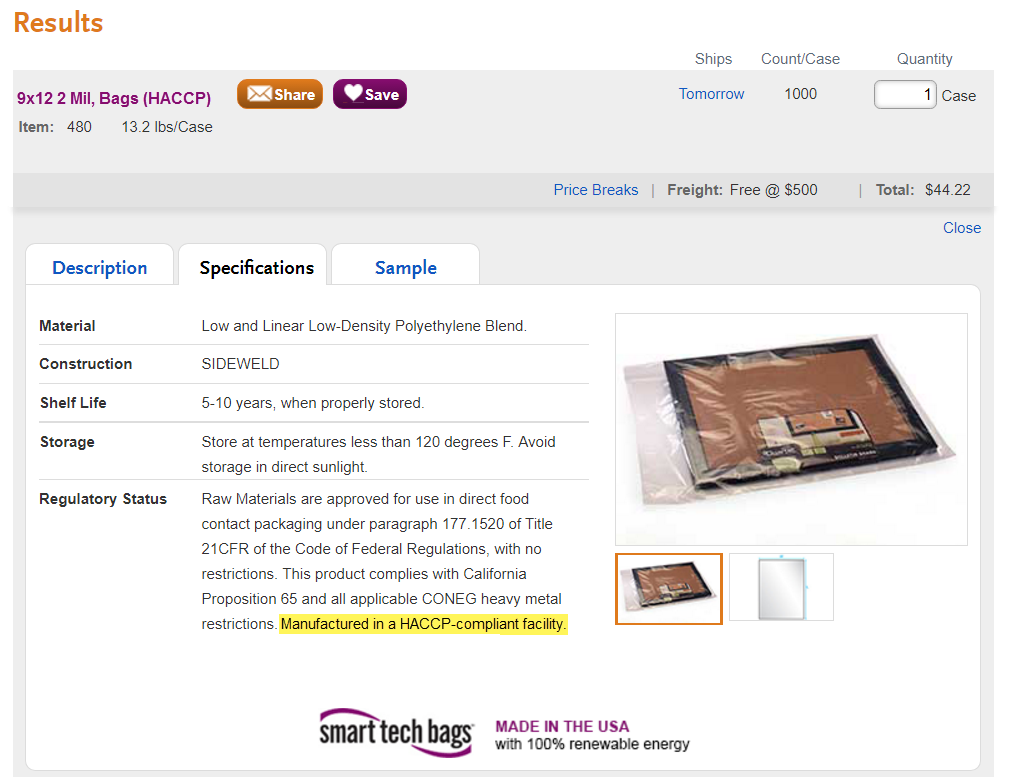

Expanded results

Add a line to the Regulatory Status section within the Specifications tab.

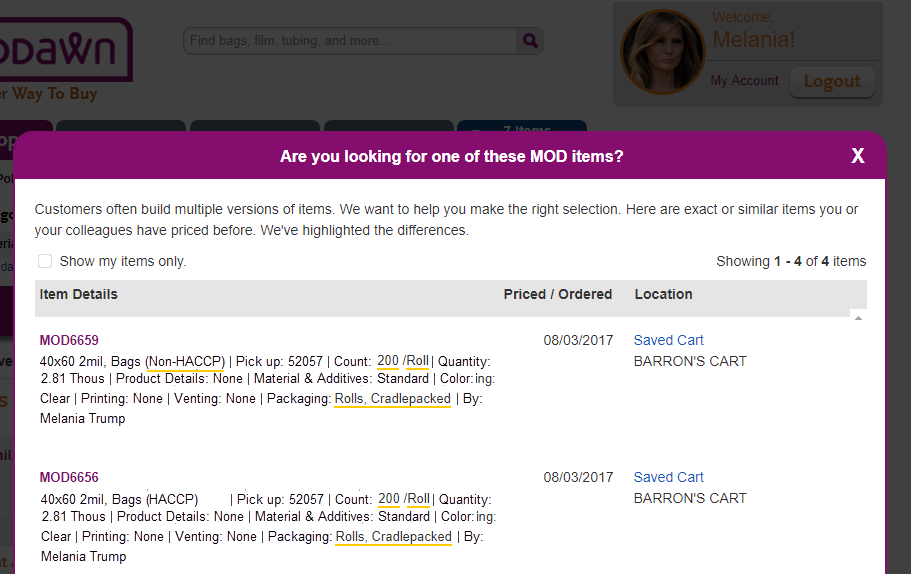

Godzilla results

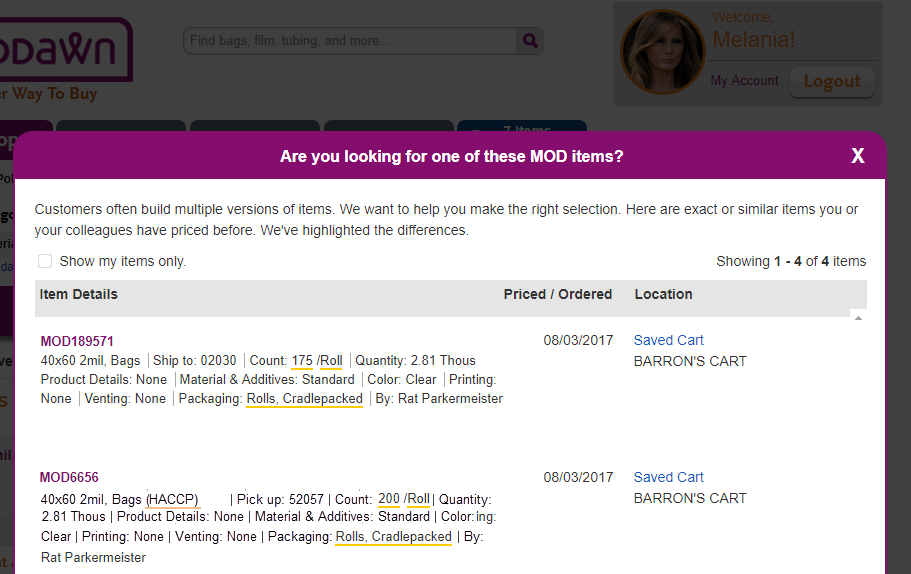

| If the user generates a HACCP result, we will include non-HACCP matches with "(Non-HACCP)" underlined as a difference. | If the user generates a non-HACCP result, we will include matches with "(HACCP)" underlined as a difference, but we will not show "(Non-HACCP)" in the product details. |

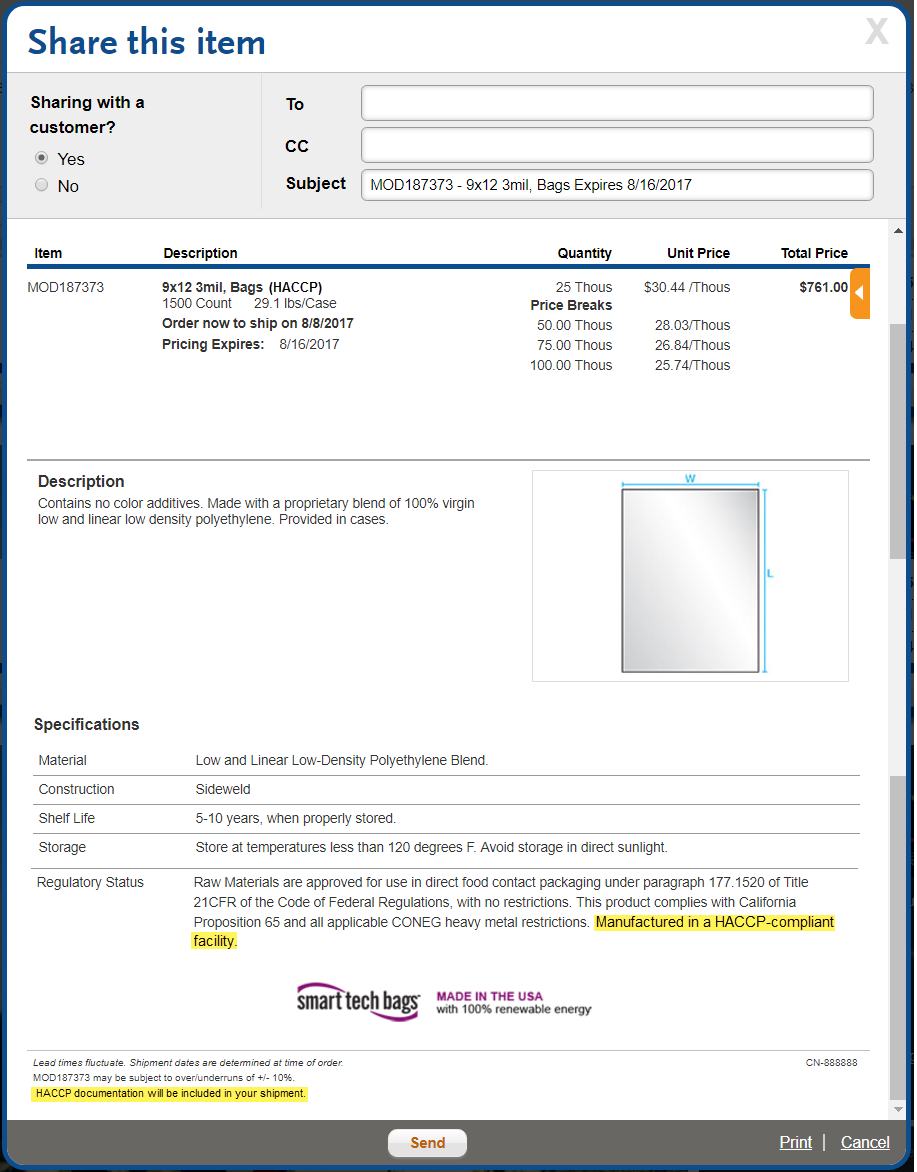

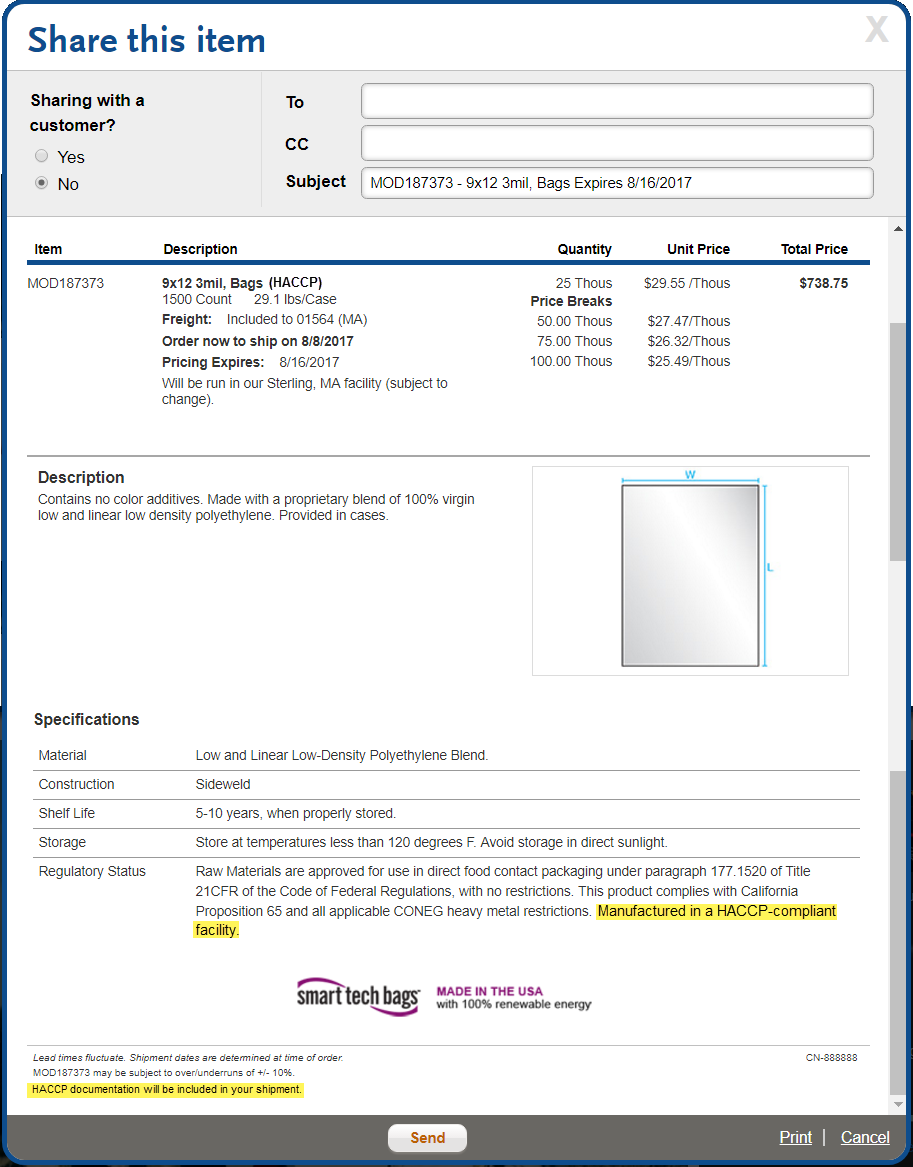

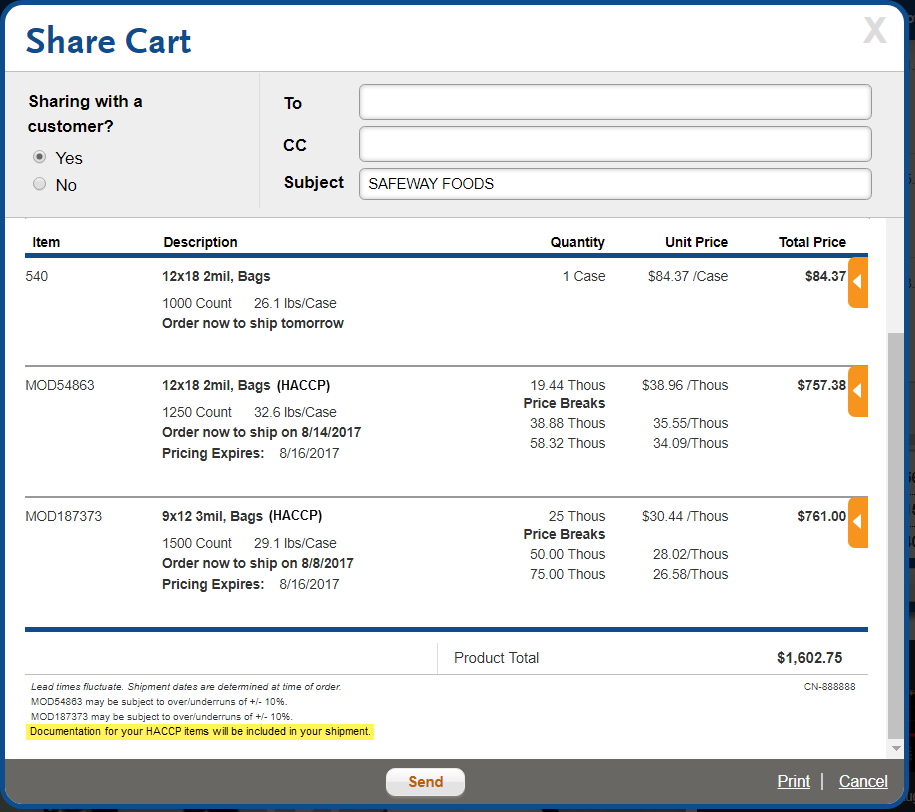

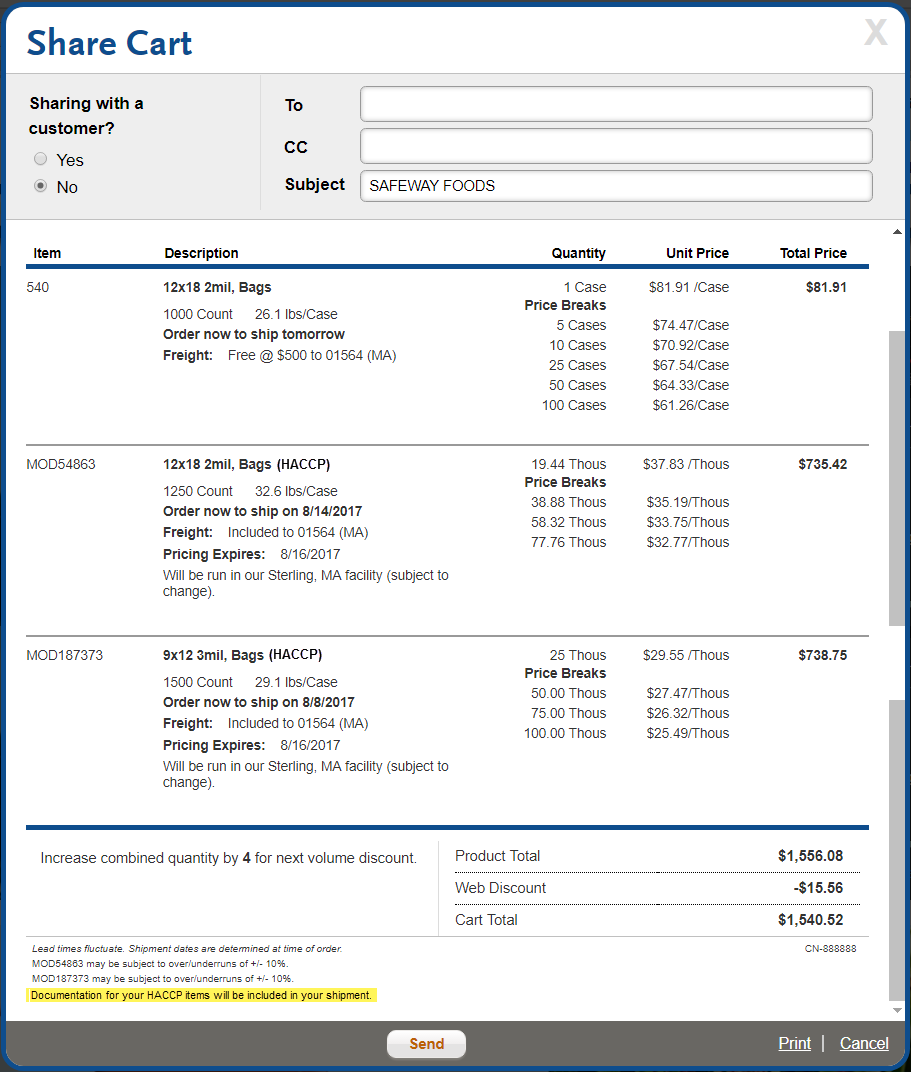

C. Share item, share cart

When you share an item, you will see HACCP in the product title, and the HACCP manufacturing blurb in specifications, same as results. When you share a cart "HACCP" in the product title is sufficient.

We've added a line to the footer section about certification documentation being included with shipment to to both shared items and carts; we felt this would be reassuring to distributors and end users.

| With customer? / YES | With customer? / NO | |

| Share Item | ||

| Share cart |

D. Order placement

We discussed including an option to have a PDF of the certification attached to the order acknowledgment and/or shipping notification, but concluded that there is no known demand for this.

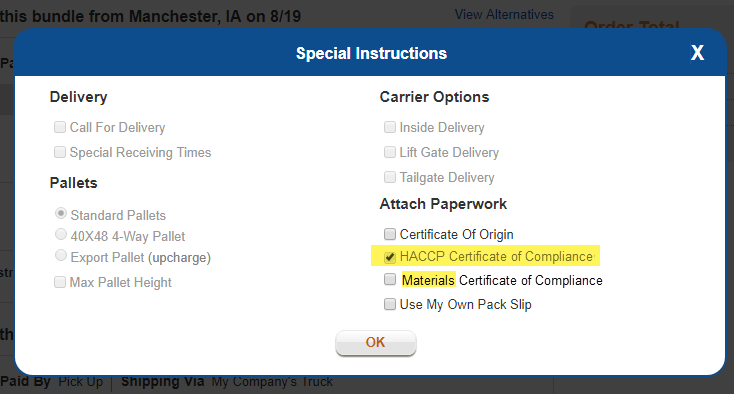

"(HACCP)" in the product descriptions will carry through to the Checkout screens. Special instructions will automatically include "Attach HACCP certificate of compliance." In the special instructions pop-up the checkbox is hard coded to be checked; ability to uncheck is disabled.

Please modify verbiage for regular C of C to include "materials" so it is distinct from HACCP C of C.

The HACCP checkbox will be

E. Shipping paperwork

HACCP certification template

We would like to automate the attachment of HACCP certification to orders. This form will be sent at shipping time from Clippership along with the packing slip. Have Clippership auto-print this. We need to take steps to ensure the dates are updated annually.

F. Reporting

< Jay, put your description here for reports that will replace Meredith's spreadsheet. >

G. Not Doing

- Initial release is for MOD results only. Stock will be excluded for now.

5 Testing

- Test to all specifications and screens above.

- Test to be sure all nested menu categories are coming up properly from proper facility.

- Be sure to view availability popups and ensure split shipments all coming from compliant facility.

- Be sure all references to HACCP are present where they should be and not present where they should not be.

6 Change management and rollout planning

When we launch, we should post revised content on our DRC; this is what we currently have: http://blog.laddawn.com/haccp-certification/ - also we should link from our Certs & Specs footer content to whatever we post on the DRC. Even if we don't provide canned certs for HACCP, this page is natural place to look for information about HACCP.

We need to ensure we capture any indicators of what the demand is for stock. Not sure yet what form this takes.

<< Which departments are affected by these changes? What are the possible negative perceptions of these changes, and how do we manage them? Articulate "what's in it for me?" for all internal and external stakeholders. Are call scripts necessary? Is advance customer outreach/communication necessary? What lead time is needed for training and other advance preparations? >>