YMAC for Tubing & Sleeves – No Stock Match

YMAC for Sheeting & Film – No Stock Match

Results Logic

Introduction

The following is a mapped out series of YMAC (You Might Also Consider) quote results to be used for selections from either Level 1 "Tubing & Sleeves" or "Sheeting & Film." After the user has finished entering their bag specifications in Level 2 & 3 this YMAC process will be used in circumstances where we are unable to generate a stock match. Our objective will be to first show our user a MOD (Made on Demand) quote of the exact request, then highlight credible stock alternatives that minimally deviate from the user's specifications.

We can immediately default to this search method if the customer chooses any of the following Level 2 categories:

- Gusseted Tubing

- Layflat Sleeves

- Gusseted Sleeves

- Single Wound

- Gusseted

- Sheets Perforated – Single Wound

- Sheets Perforated – Gusseted

Condition – No Match

The user has entered all of their item parameters and our search was unable to produce a stock match.

The Results

The following is a basic outline of how and what we will present to the customer as credible results. The first result will return an exact match to the customer request, while segments 2-10 should be considered to be the YMAC data results.

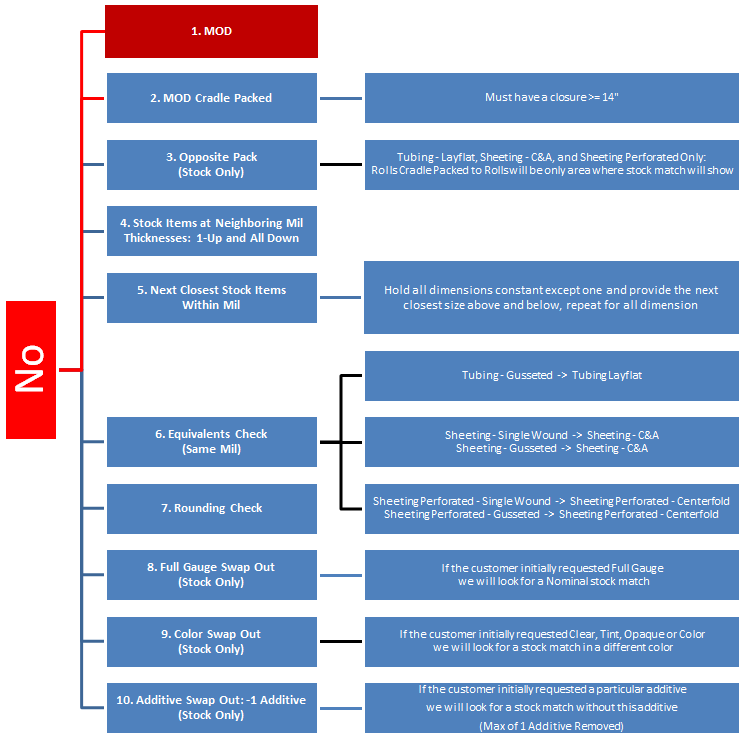

- MOD

- MOD Cradle Packed

- Opposite Pack (Stock Only)

- Stock Items at Neighboring Mil Thicknesses: 1-Up and All Down

- Next Closest Stock Items Within Mil

- Equivalents Check (Same Mil)

- Rounding Check

- Full Gauge Swap Out (Stock Only)

- Color Swap Out (Stock Only)

- Additive Swap Out: -1 Additive (Stock Only)

The Flow Chart

For "YMAC for Tubing & Sleeves – No Stock Match" and "YMAC for Sheeting & Film – No Stock Match" below you will find our flowchart, which maps out our process when a user enters a set of dimensions that we are unable to produce a stock match for. Here we can see that users will first find an exact match to their inquiry, followed by credible YMAC substitutions that can be used for their more urgent needs.

The Details

The following is a detailed review of each search result.

1. MOD

Since we don't carry an Exact Stock Match our first step will be to quote this job as MOD, when we are able (since we can't make every stock item, like black conductive tubing). This will be the customer's only opportunity (through the web) to purchase their exact request, without alteration.

We now begin the YMAC data.

2. MOD Cradle Packed

The first YMAC result is geared towards "down selling," providing the most inexpensive alternative with minimal change to a customer's request. This will be the only other time we will show the user a MOD alternative. It should be noted that not all items can be cradle packed. If an inquiry does not have a width that is greater or equal to 14" then this item cannot be cradle packed (This holds true even if a gusseted item has a combined width and depth of 14" or greater).

3. Opposite Pack (Stock Only)

This query exists to highlight various packaging methods available (Level 3 Cradle Packed to Rolls Boxed for instance), which will result in a different configuration option for the user to consider. This search is not altering any product attribute itself; rather we are looking for other stock alternatives under a different packaging option (our ability to MOD a different configuration is not related to Area 3).

4. Stock Items at Neighboring Mil Thicknesses: 1-Up and All Down

Here we are looking for a stock match under the entered dimensions, but outside of the entered Mil thickness. Here, we will take the Mil that was entered and look above, to the next stock Mil thickness up, and below, to all sequential Mil thicknesses, in an effort to find this size under a standard Mil thickness.

Example: Say a customer has entered a 60x60x0045 LD Sheets Perforated – Centerfold, which we don't have under our stock program. Here we would show two stock YMACs: 4973 – 60x60x002, and 5955 – 60x60x0015.

5. Next Closest Stock Items Within Mil

Here, we are searching for stock substitution(s) with minimal change to the user's request (staying within one of the dimensions, the Mil thickness, and all product attributes). Here, we hold all dimensions constant except one (width, depth or length) and provide the next closest size above and below, repeating this process for all dimensions.

Example: Say a customer requests 5'x100'x004 Clear C&A. First, holding the width constant we would find that there is there are no other stock alternatives at 5' wide. Next, we will hold the length constant and look for neighboring widths. Here we would show items: 4415 – 6'x100'x004 and 4410 – 4'x100'x004. Again, please note that we are not looking outside of the specified Mil thickness.

6. Equivalents Check (Same Mil)

Here we will look to alter the configuration entered by the user, to provide a relevant substitute from a different "Category" within Level 2.

The following will be the only occurrences where a category substitution will be applicable:

- Tubing - Gusseted -> Tubing Layflat

- Sheeting - Single Wound -> Sheeting - C&A

Sheeting - Gusseted -> Sheeting - C&A - Sheeting Perforated - Single Wound -> Sheeting Perforated - Centerfold

Sheeting Perforated - Gusseted -> Sheeting Perforated – Centerfold

Sheeting – Centerfold -> Sheeting – C&A is purposely not shown since a customer will be able to manually build C&A film within the Level 2 Sheeting – Centerfold category (thus we would have initially shown them a stock match).

Example: If a customer were to request 5x5x_x002 LD Gusseted Tubing we would show this user a stock alternative of 1940 – 10x_x002 LD Layflat Tubing.

7. Rounding Check

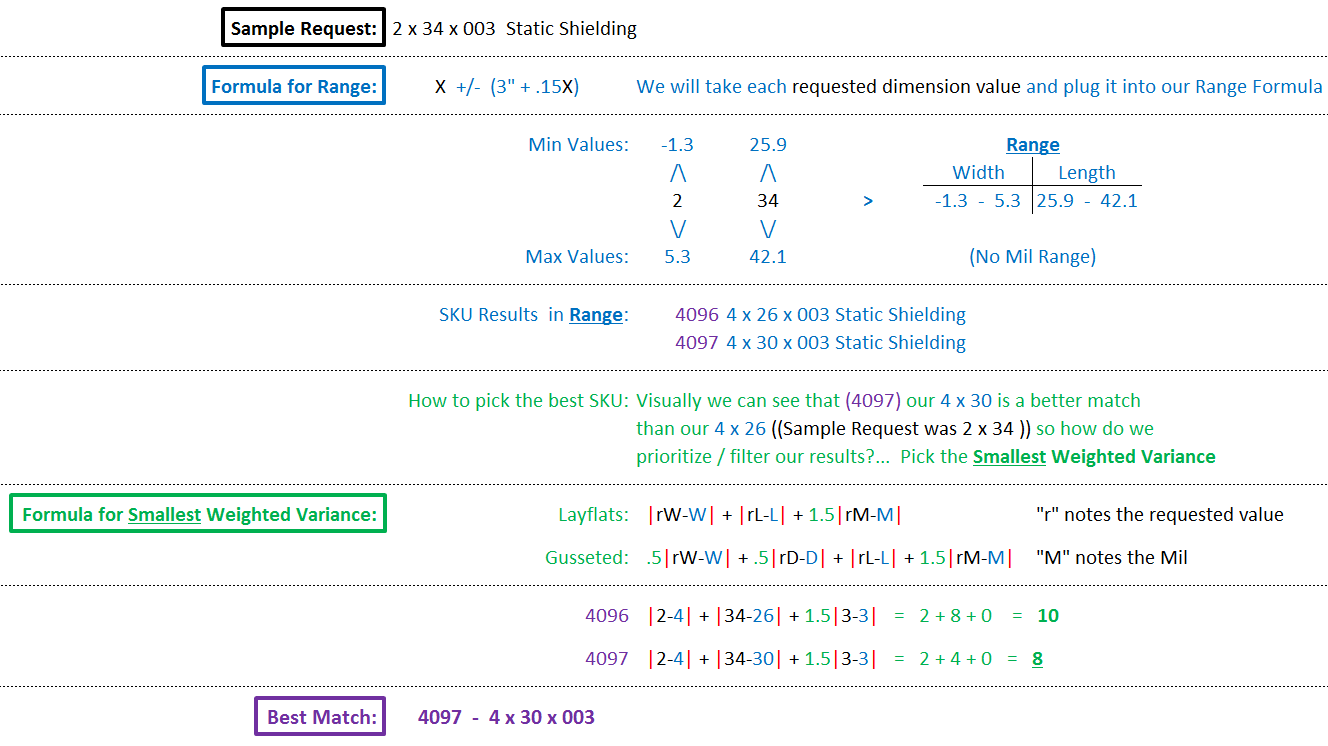

Here is a step by step process how we can systematically round to the "closest" stock alternative. We will first calculate an acceptable range that each dimension may deviate from. We will then populate a list of all the SKUs that have met this range criteria, and we will finally filter our results to show "one" result that has the smallest variance from what the user had initially requested.

I will update Area 7's sample (the data below) with an example applicable to Tubing & Sleeves or Sheeting & Film when I am next able to. However, the logic is the same as its twin in "YMAC for Bags – No Stock Match."

Notes on Area 7:

- Formula for Range: X +/- (3" + .15X)

- The 3" enables our search to find an acceptable range for smaller bags (if we were to go just off the ".15X" our single digit dimensions would not look beyond the dimension entered)

- The .15X (15%) enables our search to find an acceptable range for larger bags (if we were to go just off the 3" larger dimensions would not look far enough beyond the dimension entered)

- We can always change either of the two values

- Formula for Smallest Weighted Variance: Layflats |rW-W| + |rL-L| + 1.5|rM-M| & Gusseted .5|rW-W| + .5|rD-D| + |rL-L| + 1.5|rM-M|

- The weights, in green within these formulas, assign specific value to each deviation. This will allow us to assign value between each dimensional and Mil difference; presenting our user with one, single result (two if there was a tie)

- We can always change these weights

- |...| designates absolute value, M means Mil, & "r" notes the requested value... so |rW-W| means take the absolute value of our requested width minus the potential SKU's width

- The weights, in green within these formulas, assign specific value to each deviation. This will allow us to assign value between each dimensional and Mil difference; presenting our user with one, single result (two if there was a tie)

- Area 7 will likely reproduce results from Area 4 (Stock Items at Neighboring Mil Thicknesses: 1-Up and All Down) & Area 5 (Next Closest Stock Items Within Mil) and we must ensure that we do not to list a SKU twice in our YMACs

- This is because Area 7 is factoring in the Mil thickness and sizes available within a category, factors that are individually broken down by the two earlier Areas.

- Now we could, easily enough, just remove Areas 4 & 5 but we will lose a means to cleanly label those results (The subject labels Steve has put above our individual YMACs to quickly communicate to the user what is different about this item from what they had originally requested).

- In my (Cliff's) opinion, I would suggest that we run Area 7 for each customer request, but if our result duplicates an item listing from Areas 4 or 5 then we should hide Area 7's result (and not continue searching for a SKU that hasn't already been shown in our YMAC results)

The final three sections (Areas 8 – 10) are additional attempts, we will undertake, to find credible stock alternatives. We have very few stock SKUs for our YMAC to work with, compared to the YMAC alternatives available for bags requests. Thus we will dig a little deeper to see if we can show our users a speedy stock solution, rather than just the MOD result or no results at all.

8. Full Gauge Swap Out (Stock Only)

If the customer initially requested Full Gauge we will look for a Nominal stock match.

9. Color Swap Out (Stock Only)

If the customer initially requested Clear, Tint, Opaque or Color we will look for a stock match in a different color than what was entered.

10. Additive Swap Out: -1 Additive (Stock Only)

If the customer initially requested a particular additive we will look for a stock match without this additive. A maximum of one additive can be removed so the YMAC remains as a credible alternative, regarding the performance properties the customer sought.