7/16/13 - jbm - notes on allocation logic to be reviewed by the functional design team

Allocation Logic

Item is Manufactured in the Order Warehouse.

If it is available then ship it today. If not, then if it is available in an alternate warehouse then ship today from alternate warehouse. Otherwise, ship in three days from the Order Warehouse.

Item is Purchased in the Order Warehouse.

If it is available from the order warehouse or an alternate warehouse then ship it today from the “available” warehouse. Otherwise, if it is on a PO then ship it on the PO receipt date plus 1 day. Otherwise, its ship date will be the date calculated from the items’ purchase lead time plus one day.

NOTE: Diana thinks the purchase lead times in the system are in pretty good shape but would like to review them to be sure. She also thinks that it will be fairly rare that an item is out of stock and not on order already.

NOTE: Leo says many items ship out on the same day received but anything that is received later in the day may not go out until the next day. Hence we will add a 1 day cushion when calculating the ship dates.

Item is Transferred to Order Warehouse from another warehouse and made in the Transfer Warehouse.

If it is available then ship it today. If not, then if it is available in an alternate warehouse then ship today from alternate warehouse. Otherwise, if it is manufactured in the transfer from warehouse then ship it in 3 days from the transfer from warehouse. If it is purchased to the transfer from warehouse and is on a PO then ship it from the transfer from warehouse on the PO receipt date plus 1 day. If it is purchased but not currently on order then ship it from the transfer from warehouse using the items’ purchase lead time plus one day.

NOTES:

· The proposal above takes into consideration that the “manual” resolution of a transfer backorder situation today is derived on a case by case basis and is based on customer needs. Meme indicates that a good number of back ordered transfer items ship direct from the transfer from facility (even when other items on the order are going to be picked up). In addition, transfer back orders are a shrinking breed because we continue to expand our manufacturing capabilities throughout the organization.

· This solution is going to be most impactful on CPU orders. If a customer really wants to pick his order up he wouldn’t have the option online. He would have to Chat or make a call and have the order rerouted manually. One band aid solution to this would be to give the customer an option that indicated “this is not currently available for pick but upon placing the order you will be contacted with a pickup date”. In this way the line would show up as a back order and then the pickup date could be calculated and communicated manually.

· The logic for automating a transfer receipt date is a little bit complicated. That said, should we decide whether it is important to automate this logic. The notes below identify the two main components to the project and summarize the necessary changes.

o Gain a better understanding of the processing of individual Transfer Orders in Avante today. The life cycle of a TO can be extremely long (sometimes months) and it can move in and out of various statuses such as being Open, Printed, Shipped, Backorder. A full examination of this process will help clarify the procedure and likely invoke some process change to benefit flow.

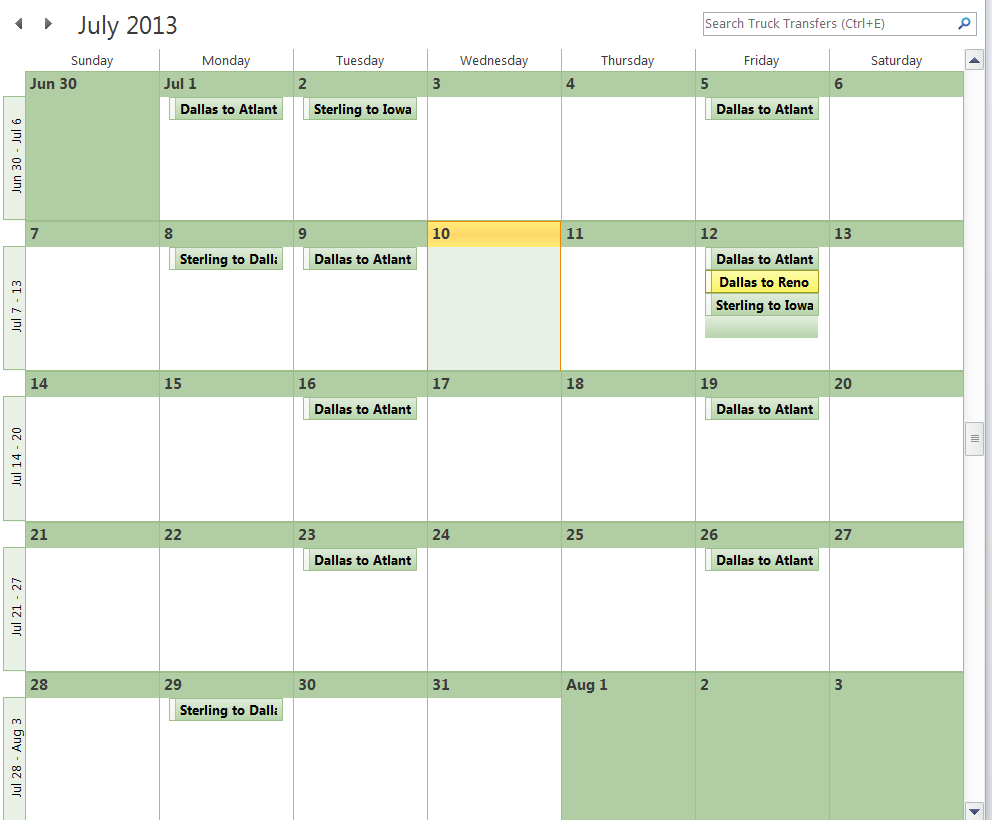

o The Transfer Truck schedule is currently in Outlook and will need to be integrated into Avante. While the Transfer Orders themselves gather and “herd” items into the “loading” area, the Transfer Truck schedule contains the actual dates that are needed to calculate accurate ship from and receive to dates.

o The summarize the logic, it would need to first determine whether a particular item is already in transit to the order warehouse and if not would use the Purchase or Manufactured logic to determine when an item will be received in the Transfer From warehouse so that it can determine what truck it will ride on and therefore what date it be received and shipped on.

7/16/13 - jbm - end notes on allocation logic

Changed to in progress to address questions RE transferred items.

Q: Going forward, how will Laddawn determine availability date for out-of-stock "transferred" items?

Today this is a manual judgment call for CE, requiring lookups in MRP and transfer truck schedule (public Outlook calendar)

A: Ideally this would be automated. Doing so is relatively straightforward for items that are being shipped (whether made or purchased), but less so for items that are being picked up.

A key consideration is how much effort we want to give to something that is becoming an increasingly rare occurrence, given Laddawn's excellent inventory forecasting and management, and new manufacturing capacity in Reno and Atlanta. An even smaller number subset of these orders will be CPU orders, given that CPUs account for less than 10% of stock orders.

The transfer truck schedule does follow a fairly predictable pattern (e.g. "a truck goes from Dallas every Tuesday and Friday") but there are enough anomalies or changes, as far as when those trucks go, and what is ultimately on those trucks (vs. what is forecasted to be on those trucks), to render the schedule unreliable for programming rules for calculating availability dates for out-of-stock transfer items. To some extent, this is a chicken-and-egg problem. Jerry Howe, alerted via MRP that a backordered item (both purchased or made?) has, ahead of forecast, gone negative in inventory at the WH that receives the transfer, will have the MW put that item on the next scheduled truck. Automation of the availability date would require moving the truck schedule and its maintenance to Avante, so that it can auto-adjust based on item searches, not just orders, and reflect revised, potential transfer dates in real time.

How it plays out for ship to v. pick up, made v. purchased....

Customer searching with ship-to zip code

- Made item - Ship from alternate warehouse in 24 hours. If not available at any AW, are any in transit from MW to PW? If so, ship date equals transfer due date (+1 day?) from MRP, shipping from PW. If none in transit, ship from manufacturing warehouse in 72 hrs.

- Purchased item - Ship from alternate warehouse in 24 hours. If not available at any AW, are any in transit from MW to PW? If so, ship date equals ship date equals transfer due date (+1 day?); shipping from PW. If none are in transit, availability date = receiving date on purchase order in MRP, shipping from AW. (If no PO in MRP, availability date = PO lead time in MRP (need to confirm). An actual order will create negative inventory, which will trigger notification to Purchasing Dept to issue PO.)

Customer searching with pick-up zip code

- Made item - options for discussion

Are any in transit from source warehouse? If so, give transfer truck due date whether made or purchased. If not....

Actual availability date for pick up at primary warehouse = the date of the soon est transfer truck following manufacturing lead time, plus three day transit time...- Option 1 - Manual workaround - Similar to warning for MOD result, give message for search result that item is on backorder for this warehouse, and cannot be picked up ...at this time. Prompt user to enter a ship-to zip code and re-run search, or to call CE to determine a pickup date, using same research methods they use today. User cannot share, save or add to cart until they perform one of these actions. If they call CE for a pickup date, CE needs a means of effecting a change to allow the item to be picked up on that date.

CON - Could lose the sale. Risk giving the wrong impression about how long it will take to replenish inventory. Having to pick up the phone is a barrier. - Option 2 - Manual workaround - determine a generic best guess based on average manufacturing lead times and intervals between transfer trips - perhaps table-driven, warehouse-specific; perhaps not (one-size fits all). Serve this date up every time a transfer item is not in stock. For example, let's call it 8 days for Atlanta. This availability date carries through from search results to checkout, for as long as the item is still out of stock at Atlanta. (If there is a long lag time between checking stock and customer actually placing the order, availability is likely to change.) For web orders, shipping alerts CE if there is a substantial discrepancy between the actual ship date, and the one the customer expected - if the actual ship date is a day or more later than the expected ship date. CE alerts the customer. For phone/fax orders, when CE is running the original stock lookup for the customer, the 8 day date will alert CE to the transfer issue, and they can determine the actual pick up date, using the same research methods they use today. Can we provide them a means of overwriting the date?

CON - Extra work for Shipping Dept. Could be error-prone process for both CE and Shipping. - Option 3 - Automated solution providing precise date, based on manufacturing lead time and transfer truck schedule. Requires incorporation of real time transfer truck schedule into Avante.

CON - Potentially a lot of programming effort for little gain. Also, by the time we program it for current conditions, the transfer truck schedule and roster of items that get transferred will change dramatically as Reno production ramps up and Atlanta production comes online.

- Option 1 - Manual workaround - Similar to warning for MOD result, give message for search result that item is on backorder for this warehouse, and cannot be picked up ...at this time. Prompt user to enter a ship-to zip code and re-run search, or to call CE to determine a pickup date, using same research methods they use today. User cannot share, save or add to cart until they perform one of these actions. If they call CE for a pickup date, CE needs a means of effecting a change to allow the item to be picked up on that date.

- Purchased item - Actual availability date for pick up at primary warehouse = the soonest transfer truck following receipt date on purchase order in MRP (or PO lead time, if no PO) plus three day transit time. Same options as for made items?

- Made item - options for discussion